Research and Development

We are engaged in research and development based on two main concepts.

1. “Basic Research” toward Zero CO2 Emissions

As a manufacturer of industrial furnaces, which play a key role in thermal processes in a wide range of industries, we are actively working to improve energy efficiency and decarbonize the industry through the use of next-generation fuels. Specifically, we are conducting basic research and development on the use of carbon-free fuels (hydrogen, ammonia, etc.), which do not emit CO2 during combustion, and on the development of higher output electric heaters with an eye to expanding the use of green electricity.

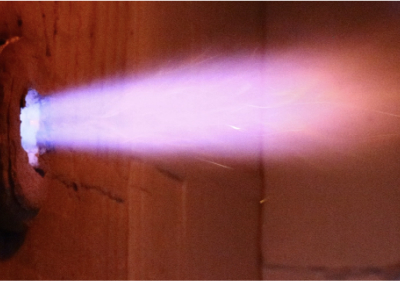

Hydrogen Combustion

In collaboration with industry and academic institutions, we are engaged in joint demonstration experiments related to hydrogen combustion technology. We are also conducting basic research on the characteristics of hydrogen combustion, basic research on the application of our energy-saving combustion control technology to hydrogen combustion, and verification of the effects of hydrogen embrittlement on metal products during heat treatment at our own plant.

Ammonia Combustion

In collaboration with industry and academia, we are engaged in basic research on the use of ammonia in industrial furnaces. Specifically, we are conducting research on methods to control the generation of toxic gases when ammonia is mixed with combustion and the effects of ammonia combustion gases on materials to be heated.

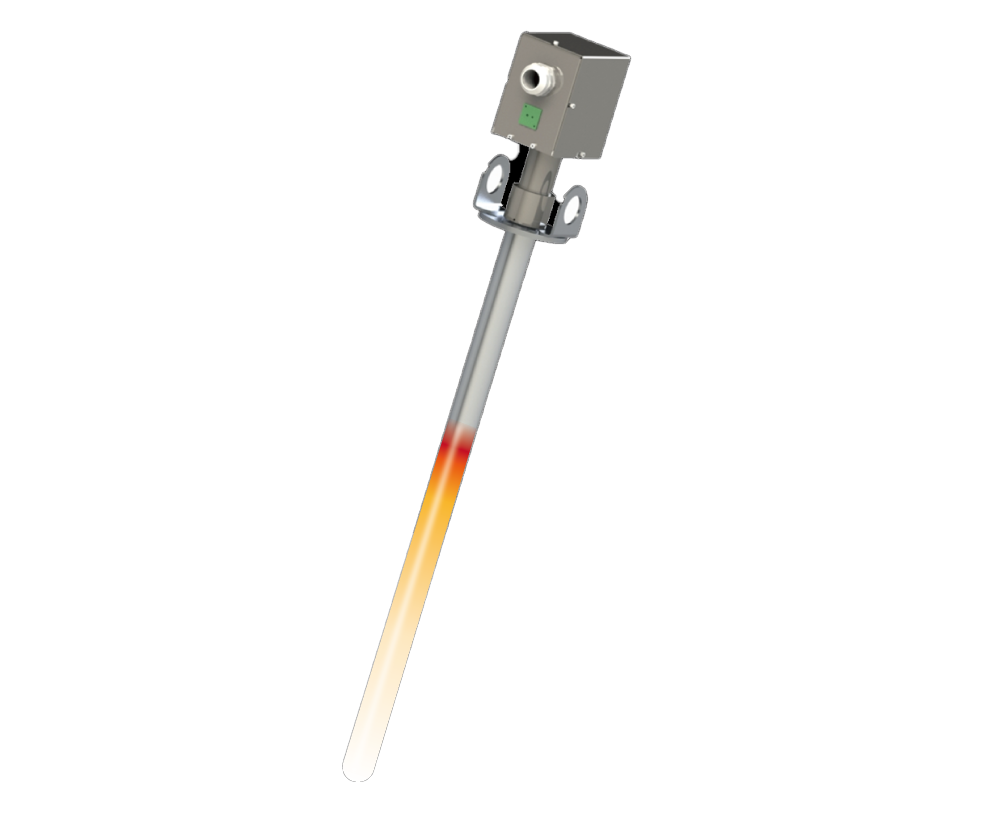

Increasing the Output of Immersion Heaters

We are improving the high output immersion heater (SA heater) used for melting and holding molten aluminum.

The SA heater is characterized by its higher output compared to other companies’ products (maximum output of 27 kW), but we are aiming for even higher output and improved durability.

2. “Development” of equipment that meets customer needs

We not only follow the specifications provided by our customers, but also pursue the optimum heating and cooling processes for their products through repeated demonstrations using test equipment.

Heat Treatment Testing of Products

We have test equipment that can perform T5/T6/T7 heat treatment of aluminum products and heat treatment of titanium alloys, and use this equipment to verify product hardness, residual stress, etc.

Development of CFRP Recycling Equipment

We had no experience in CFRP (carbon fiber reinforced plastic) combustion, but in order to meet the needs of our customers who wanted to recycle (pyrolyze) CFRP, we installed test equipment in our plant to investigate the optimal processing conditions, and based on the results, developed and delivered CFRP recycling equipment to our customers.