Real story behind the development of a product 2

The world’s first all-electric melting furnace was developed by the challenging spirit of young employees -Recycle-related equipment

In the 2000s, there was a worldwide reevaluation of nuclear power generation, known as the nuclear renaissance, and this was accompanied by a flurry of research and development in this field in Japan under various subsidy policies that encouraged the use of electricity.

This section introduces the story of the development of the all-electric furnace, the world’s first innovation created by our company in this era, which has been attracting renewed attention from customers in recent years as we work toward the realization of carbon neutrality.

Character

Senior Engineer:Ms. M

Joined the company in 2009. She has experience in both sales and design work, and has earned the trust of customers, especially in the aluminum field. Recently, she feels that more and more customers are considering carbon neutralization of industrial furnaces, such as heater use.

Young employee:Ms. O

A young employee who joined the company in 2022. She mainly designs aluminum melting furnaces. She hopes to hone her skills and someday develop new technologies herself.

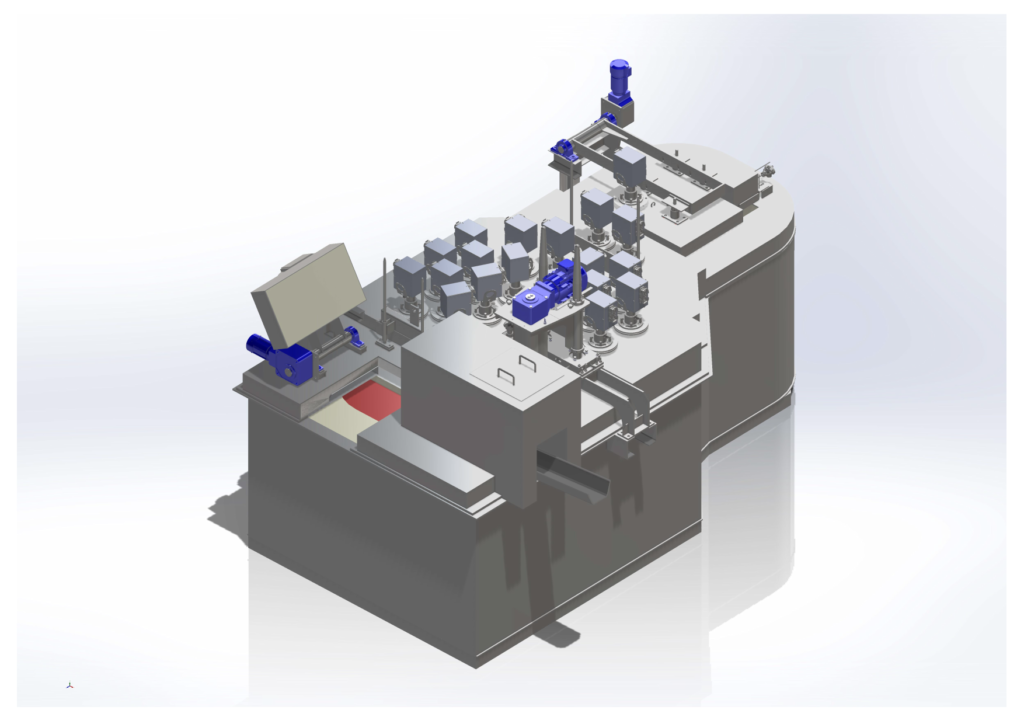

All-electric aluminum melting furnace (S-MIC)

Equipment that uses electric heaters to melt and hold aluminum.

Zero CO2 emissions from the plant.

Development started in 2008, mainly by young employees.

Ms. O:

Ms. M, nice to meet you today.

Ms. M:

Nice to meet you today. I heard that you would like to work in technology development someday.

Ms. O:

That’s right!

Recently, I feel that there have been so many inquiries about S-MIC (S-MIC).

I heard that it was the world’s first all-electric aluminum melting and holding furnace developed by young employees, and I wanted to develop such an amazing facility someday…

This equipment was developed right around the time you joined the company, wasn’t it?

Ms. M:

Yes, we delivered the first unit in 2010, when I was in my second year with the company, the same as you. My senior who had been with the company for 5 years was in charge of the development, and I remember thinking how amazing he was.

When you were in elementary and junior high school, you started to hear the word “all electrification” a lot, didn’t you? At the time, there was a huge boom in electrification due in part to the national policy, and naturally the industrial furnace industry was also getting excited about building industrial furnaces that use electricity to further save energy and drastically reduce CO2 emissions from aluminum melting furnaces!

However, it seems that the development of an all-electric melting furnace was quite a hurdle for any company.

Ms. O:

Why was that?

High-power heater created by overcoming problems during development

Ms. M:

I think the main reason is that the electrical energy required for melting is so large that it is difficult to develop heaters that meet the requirements. The higher the output of a heater, the less stable and durable it becomes, and the more likely it is to break.

Ms. O:

Indeed, it takes a tremendous amount of energy to raise the temperature of aluminum to its melting point of 660°C….

As I recall, the S-MIC was developed jointly with the Tokyo Electric Power Company, right? And the SA heater (Sanken Atherm Heater) used in the S-MIC was developed jointly with ATHERM of France. That is quite a big project, isn’t it?

Ms. M:

Yes, it was! In cooperation with various companies, young employees worked together to develop an all-electric melting furnace, which no other company was able to achieve at the time.

Ms. O:

You must have gone through a lot of hardships during the development. Do you have a story that left a lasting impression on you?

Ms. M:

What surprised me the most at the time was the rupture of the heater. I was at the factory that day and heard a loud noise as if something had shattered inside the equipment being tested. I pulled up the heater with trepidation and was surprised to see the remains of the heater with the tube shattered.

I immediately contacted ATHERM to gather data on the shock resistance of the tubing, heater materials, and construction, and we used this information to brainstorm about possible causes. We tested several hypotheses, such as whether the heater was short-circuited or whether the heater tube was defective, and found that, due to the characteristics of the heater material, the inside of the heater became extremely pressurized when heated, putting a load on the tube.

Ms. O:

This was truly an exploratory development. I guess a spirit of challenge and a never-give-up attitude are important in the development of new technologies.

High-output immersion heater (SA heater)

This original immersion heater surpasses other products in all aspects of high output, high efficiency, and compactness.

Fusion of past know-how and new technology

Ms. M:

That’s not all…S-MIC has many areas where we learned and utilized Sanken’s know-how up to that point.

Ms. O:

…Are you talking about the part where you use immersion heaters? At a factory I visited the other day, I saw a plating furnace with the same kind of immersion heating, albeit with burners.

Ms. M:

Very perceptive! Besides the use of electric heaters, S-MIC has two other major features: “immersion” and “circulation.” “Immersion” is from the immersion tube burner-heated plating furnace (developed in 1986) that Ms. Ohde saw, and “circulation” is from a large immersion melting furnace that uses a molten metal circulator to create a vortex to melt aluminum chips The “circulation” was inspired by the “Hiraro” furnace (developed in 1999), a large immersion melting furnace that uses a molten metal circulator to create a vortex to melt aluminum chips. Both are effective ways to melt aluminum with less energy.

(Photo: Circulation of molten metal))

(Photo: Immersion tube burner in a plating furnace that inspired the idea)

Ms. O:

The reason for the success of the S-MIC development is not only because you were able to create heaters that did not exist in the world with a challenging spirit and a never-give-up attitude, but also because you were able to successfully integrate the know-how you had accumulated in the past.

Ms. M:

Yes! Ms. O, don’t forget your willingness to take on the challenge of developing new technologies, and be sure to study the technologies and know-how that your seniors have accumulated.

Recently, the number of customers who are working on carbon neutrality is especially increasing, and the development of new technologies is required in many areas, such as all electrification, hybridization of electricity and gas, use of carbon-free fuels, and small modifications to increase energy efficiency.

We’re also working on heater improvements through a capital tie-up with ATHERM in 2020.

Ms. O:

I understand! I will take the in-house lectures and do my best!