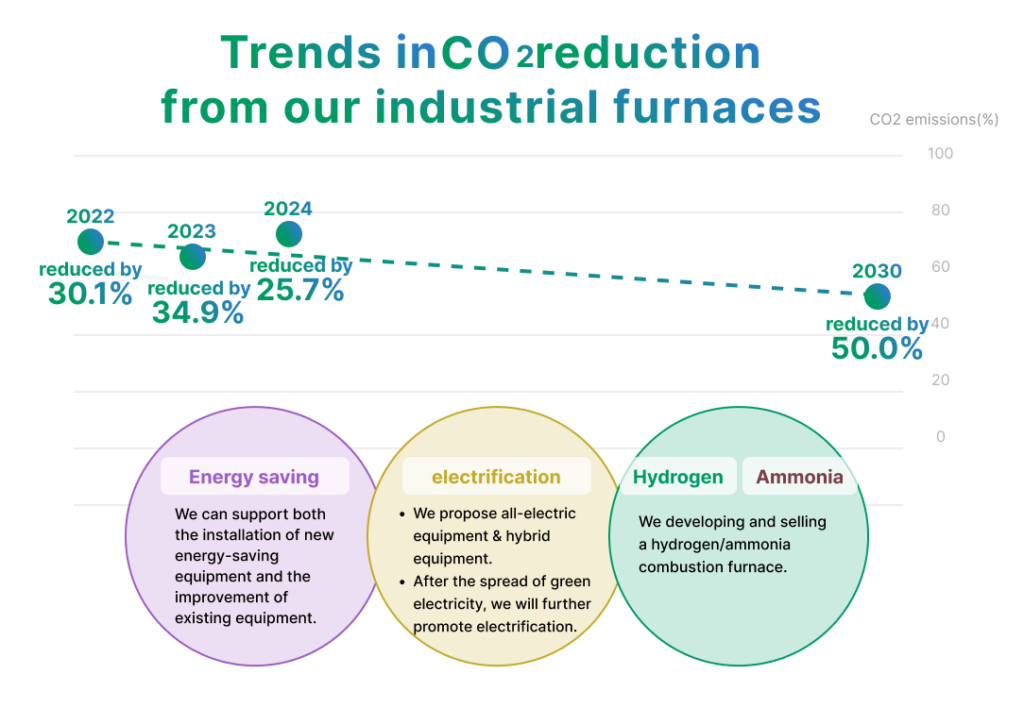

Targets

Reduce CO2 emissions from our own industrial furnaces by 50% by the year of 2030.

As governments around the world set targets for significant reductions in CO2 emissions, companies are also expected to develop technologies focused on these environmental measures.

In particular, industrial furnaces are responsible for heat processes in a wide range of industries and account for about 12% of Japan’s carbon dioxide (CO2) emissions, making decarbonization through improved energy efficiency and the use of next-generation fuels an urgent issue for manufacturers of industrial furnaces.

In response, we have set a bold goal of “reducing CO2 emissions from our industrial furnaces by 50% by the year of 2030,” and we are making company-wide efforts and advances to develop technologies and products that will contribute to decarbonization, while expanding these technologies and products throughout the world, in cooperation with our customers, partner companies, universities, and other institutions.