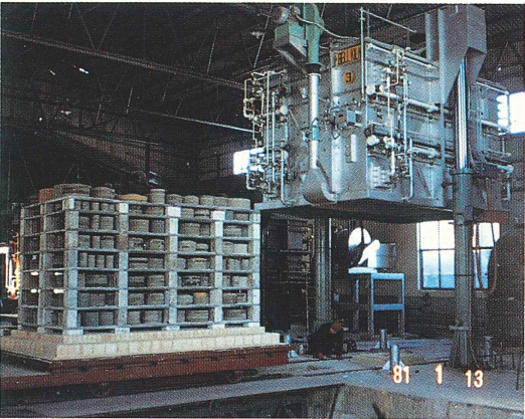

Bogie type heat treatment furnace

Product Overview

This is a standard furnace type equipment in which a cart loaded with product is charged into the furnace for heat treatment. This furnace has a proven track record, mainly in the casting/ forging steel, heavy industry industries, and is also capable of heat treating of various sizes and materials. We have been delivering these furnaces to our customers since the early 1960s, and they have been used for a long period of times.

The main features of theses systems include roof regenerative burners and a self exhaust heat recovery burners, which can efficiently utilize waste heat. In addition, we have incorporated world-class energy-saving technologies such as a waterless structure that does not use cooling water, a mechanical seal mechanism that seals the openings to minimize heat loss, and a unique individual flow control system that optimizes the air ratio for each burner to minimize energy loss.

Main Applications

- Annealing treatment of large can products

- Solution treatment of stainless steel products

- Annealing treatment of castings

Other Achievements

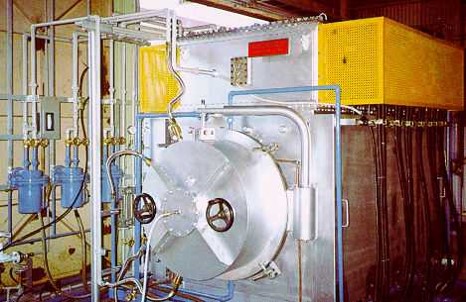

Mobile Furnace Body Type Heat Treatment Furnace

(equipment delivered to DMG MORI CASTECH CO., LTD. )

Product Overview

This equipment performs heat treatment by moving the furnace to a position where the products have already been set rather than charging the products in the furnace. When heat-treating large products that are heavier than the equipment, the furnace can treat the products without moving them, thereby reducing transportation energy and basic construction costs. This also reduces work safety risks caused by transporting heavy products with heavy machinery.

Main Applications

- Annealing treatment of large can products

- Annealing treatment of large castings

- Homogenizing treatment of special steel

Fixed Furnace Bed Type Heat Treatment Furnace

Product Details

This equipment is best suited for small-lot, high-mix production where treated materials are loaded and unloaded from a single front door using a charging and extraction device such as a fork charger (manipulator). We have a lot of experience with small to large furnaces, and can design a furnace that meets your needs.

The main features of the furnace include high sealing performance due to the single frontage (charging door), which prevents temperature drop (energy loss) and temperature distribution disorder (quality deterioration) caused by outside air infiltration. Furthermore, proper burner combustion and furnace pressure control minimize opening losses when the door is opened.

In addition, heat patterns can be changed from batch to batch and the system can be automated by installing a dedicated manipulator.

Main Applications

- Quenching and tempering of special steels

- Heat treatment of aircraft parts

- Annealing treatment of forged parts

Other Achievements

Two-section vertical heat treatment furnace

Product Overview

This heat treatment furnace can heat long forged products such as turbine rotor shafts and propulsion shafts of large ships while standing. The two-part structure of the furnace body allows products to be handled horizontally, eliminating the need for conventional deep pits and overhead cranes with high lifts. This is our unique ground-mounted heat treatment furnace that combines workability and heat treatment performance.

Main applications

- Heat treatment of turbine rotors and blades for power generation

- Heat treatment of rolling rolls

- Heat treatment of crankshafts

Other Achievements