Features

Productivity improvement

By having two heat treatment positions (bases/positions), the product treatment cycle can be significantly improved. For example, during heat treatment in one position, the next product can be set in the other position. As soon as the heat treatment is finished, the heat treatment of the prepared product can be started.

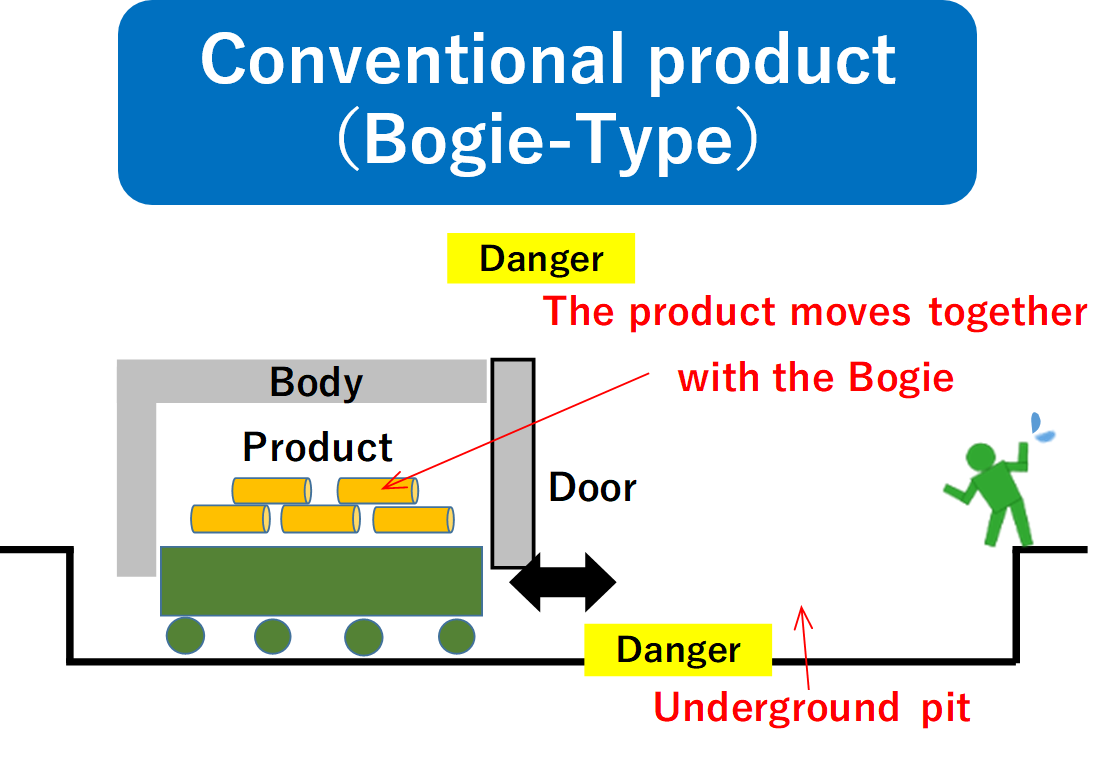

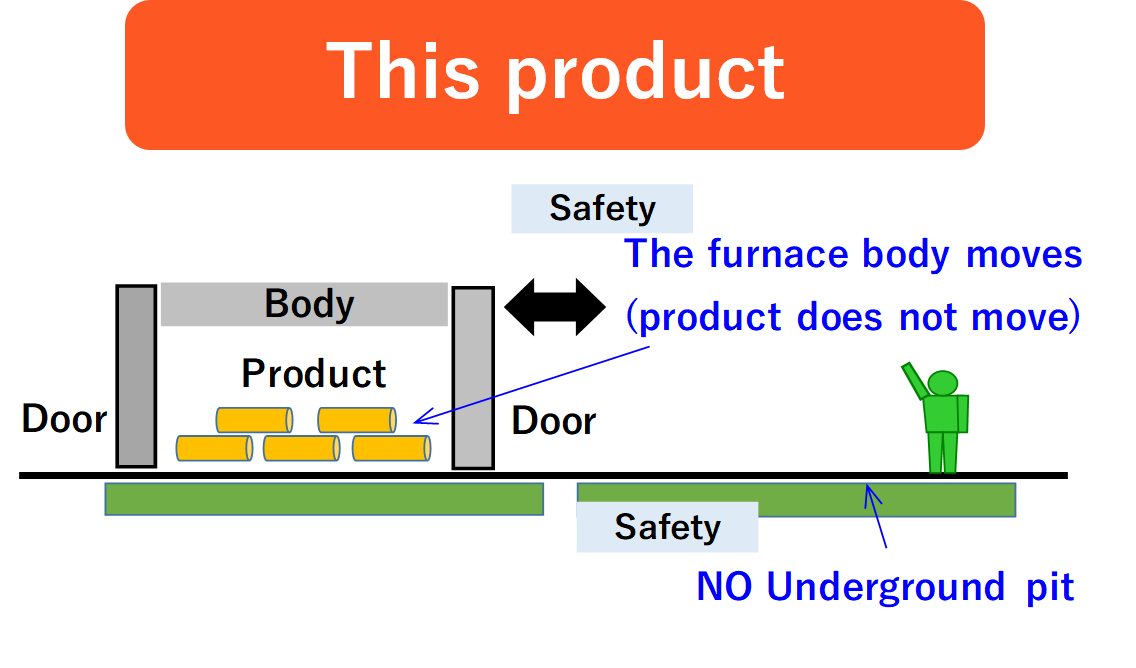

High Safety

Since the furnace body moves on the floor level, unlike the conventional cart type, it eliminates steps, thus reducing the risk of workers falling from the floor into the pit and from the cart to the floor/pit. In addition, the risk of cargo collapse is minimized because the furnace body itself moves and the product does not.

Energy Saving

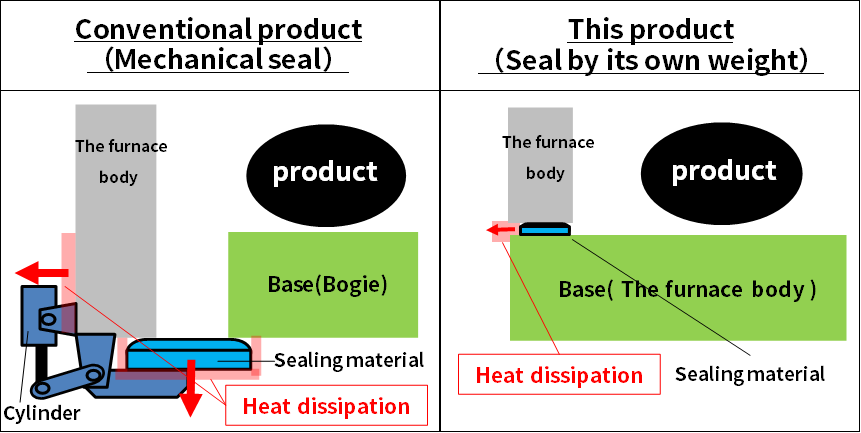

Roof regenerative burners and self-recuperative burners that can efficiently utilize exhaust heat are used. Furthermore, we are able to incorporate world-class energy-saving technologies, such as our unique individual flow control system that optimizes the air ratio for each burner to reduce energy loss. Air springs are also available to seal the furnace body under its own weight, ensuring a high level of sealing performance with a simple mechanism.

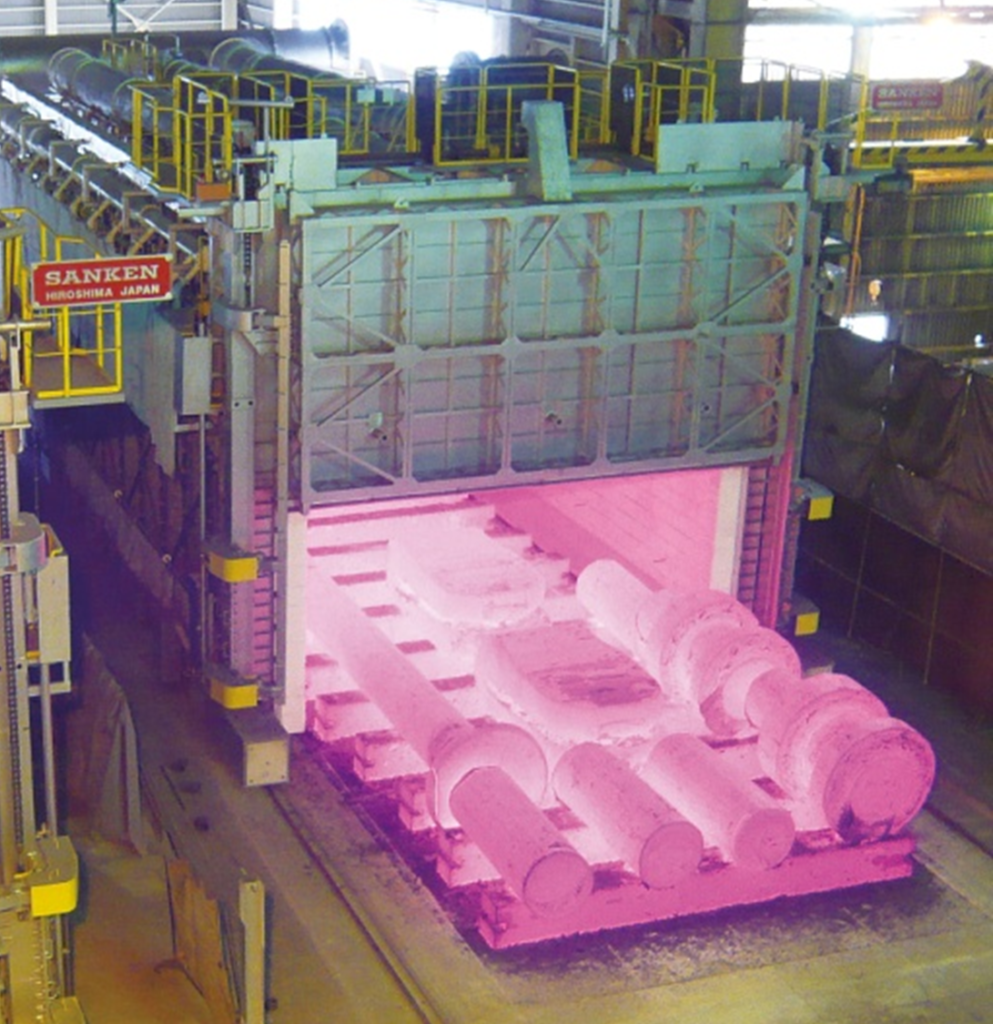

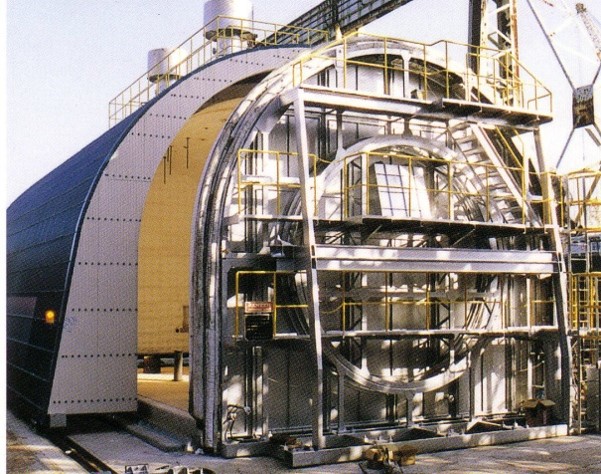

Developing the world’s first technology to move furnace bodies

In the 1980s, we developed the world’s first equipment based on the new concept of moving the furnace body instead of the product, we have delivered this equipment to customers in various fields, including shipbuilding, energy, and machine tools.

Variations

Wide range of sizes available

The optimum size of heat treatment furnace can be accommodated according to the size of the product to be heat treated.