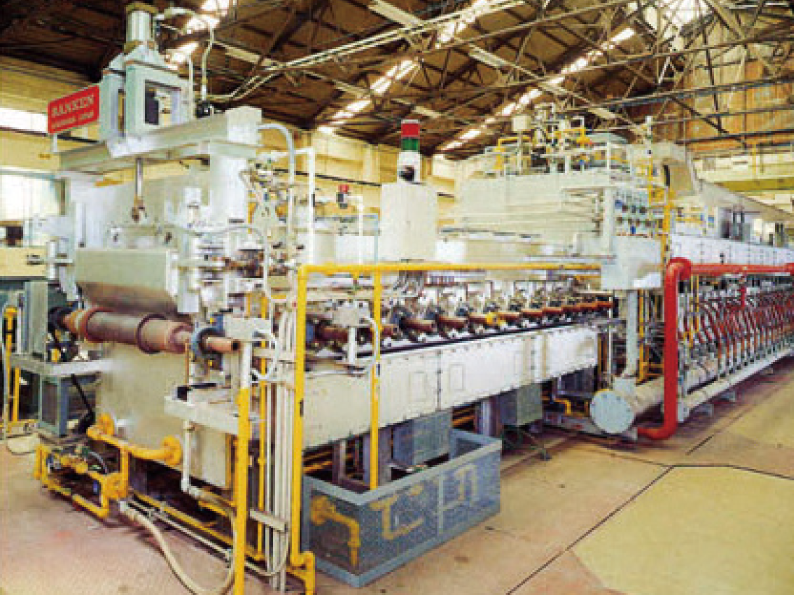

Billet Continuous Heating Furnace

Product Overview

We have delivered more than 100 units of continuous heating furnaces for rolling of general steel products such as bars, billets and other shapes all over the world. We can accommodate by our pusher type/walking beam type/walking hearth type furnaces, etc. (Large walking beam type furnaces are also available as well). (We have a technical alliance with Chugai Furnace Manufacturing for large walking beam type furnaces.)

These furnaces save energy through various methods, such as the use of a high-efficient exhaust heat recovery burners, high-precision air ratio control by our unique individual flow control system, ceramic fiber skid pipes, and waterless partition walls to reduce water cooling energy losses.

The patented highly insulated skid button and skid shift structure of the beams in the furnace, which constitutes the walking beam furnaces’ conveyance while reduces skid marks (scratches, etc.).

Main Applications

- Pre-rolling heating of steel shapes

- Pre-rolling heating of rebar

- Pre-rolling heating of wire rod billets

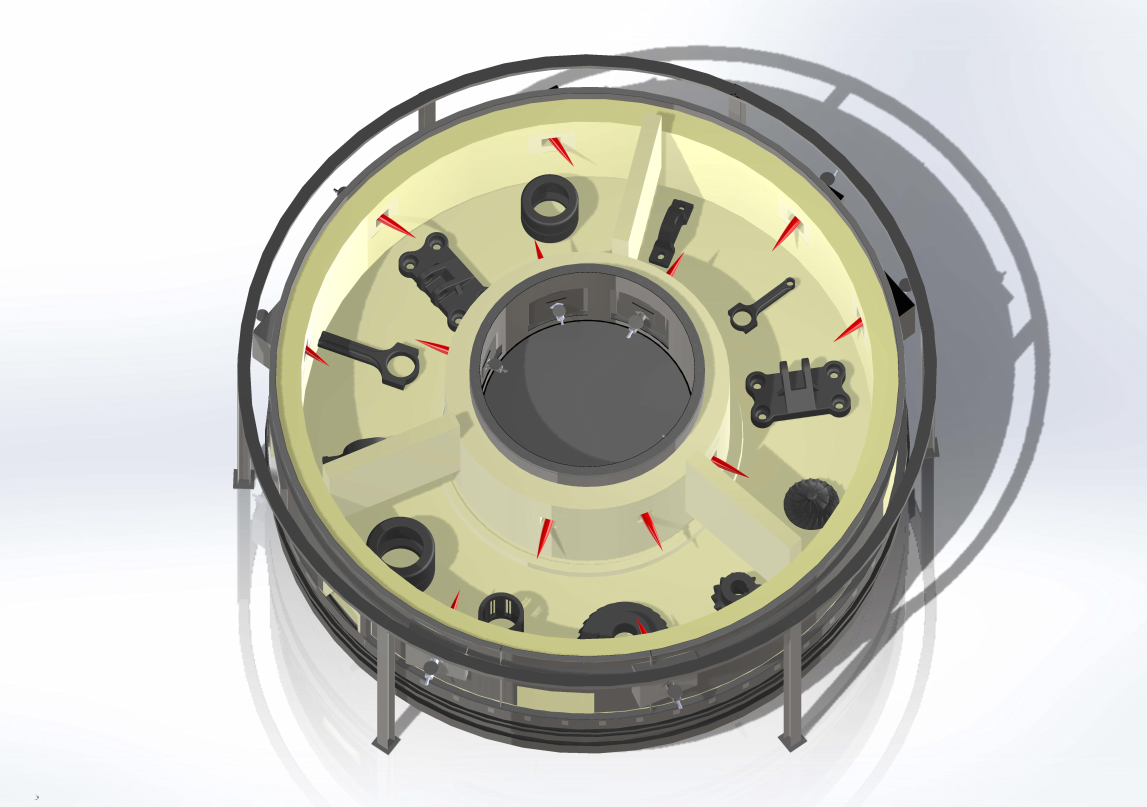

Rotary Hearth Furnaces

Product Overview

This equipment conveys and heat treats work pieces by rotating the furnace’s floor.

This type of continuous furnace has the fewest restrictions on the shape and size of the work pieces to be processed, and can be used for a wide range of work piece shapes, making it a highly a versatile/flexible type of continuous furnace.

The main features include a single frontage (charging door) for better sealing, which reduces temperature drop (energy loss) and disturbance of temperature distribution (quality loss) due to outside air infiltration. Furthermore, proper burner combustion and furnace pressure control minimize opening loss when the door is opened.

Main Applications

- Pre-heating before hot forging for automotive parts

- Pre-rolling heating of special steel

Roller Hearth Type Heating Furnace

This is a continuous furnace in which products are conveyed by special steel rollers or ceramic rollers. It can be used for various materials such as heating of special alloys and heating for hot presses. We can also flexibly respond to customer needs with gas burners, radiant tube burners, electric heaters, etc.

Heating Furnace for Hot Stamping

This is a heating furnace for hot stamping used to reduce the weight of automobiles. We have experience with both direct and indirect heating methods, and have experience with combustion as well as electric heating with heaters and hybrid systems that employ both. We have also designed and developed our own oxidation prevention system and dew point control system.

We can also provide line support, including front-to-back conveyance.

Heating Furnace for Special Steel Slabs

Non-oxidation heating furnace for special steel slabs, capable of heating up to an extremely high temperature of 1300°C inside the furnace as a roller hearth type.