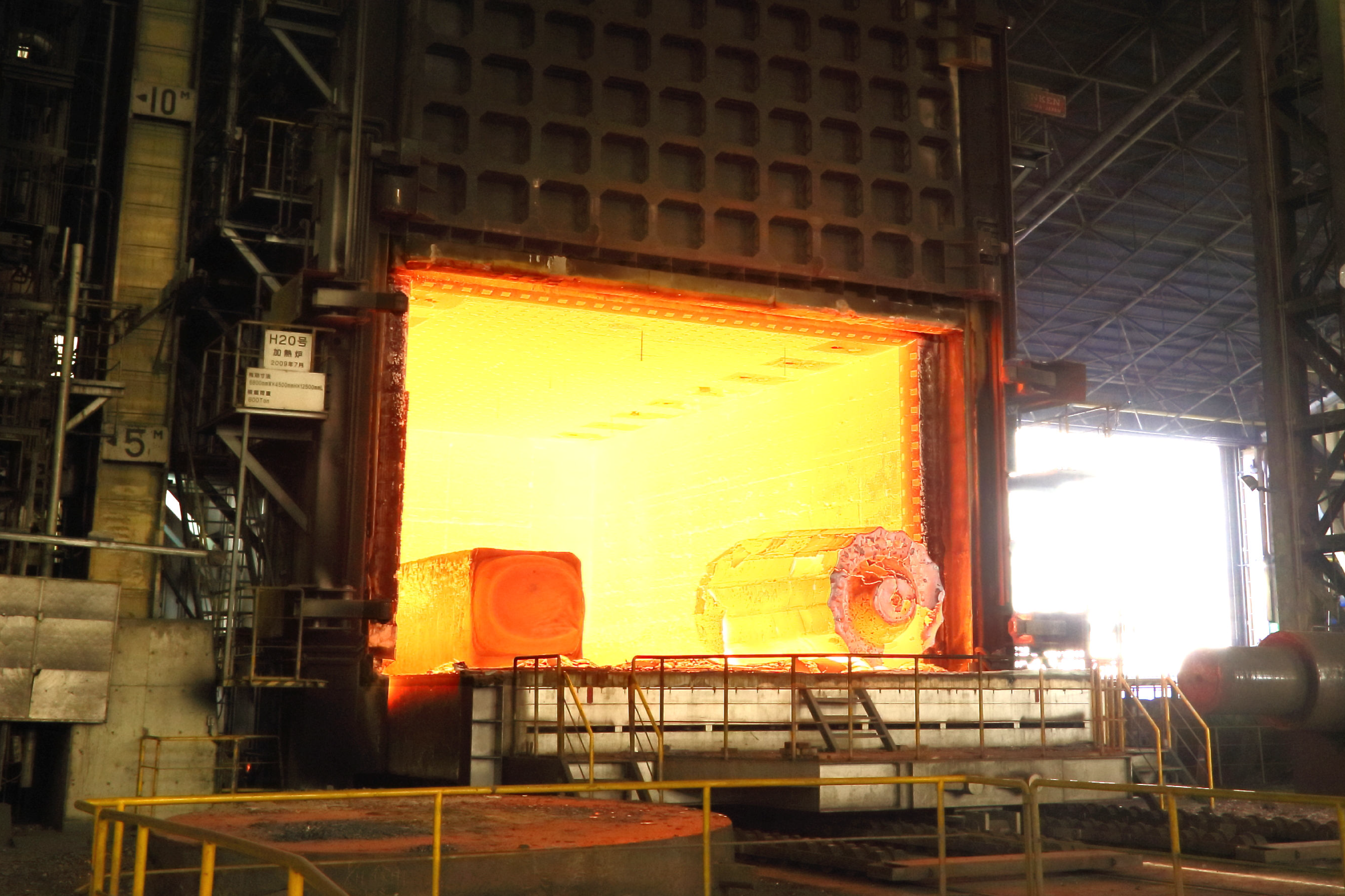

Bogie Heating Furnace

Product Overview

This is a standard furnace system in which a cart loaded with products is loaded into the furnace for heating, and we have a large number of experience with small to ultra-large furnaces, including one of the world’s largest furnaces capable of heating steel ingots weighing 650 tons each. The use of carts separates the heating space from the loading/unloading space, allowing for simple plant layout design, such as overhead cranes and aisles for transport vehicles.

Main Applications

- Pre-heating of turbine rotors for power generation prior to hot forging

- Pre-heating of rolling rollers prior to hot forging

- Pre-heating of crankshafts prior to hot forging

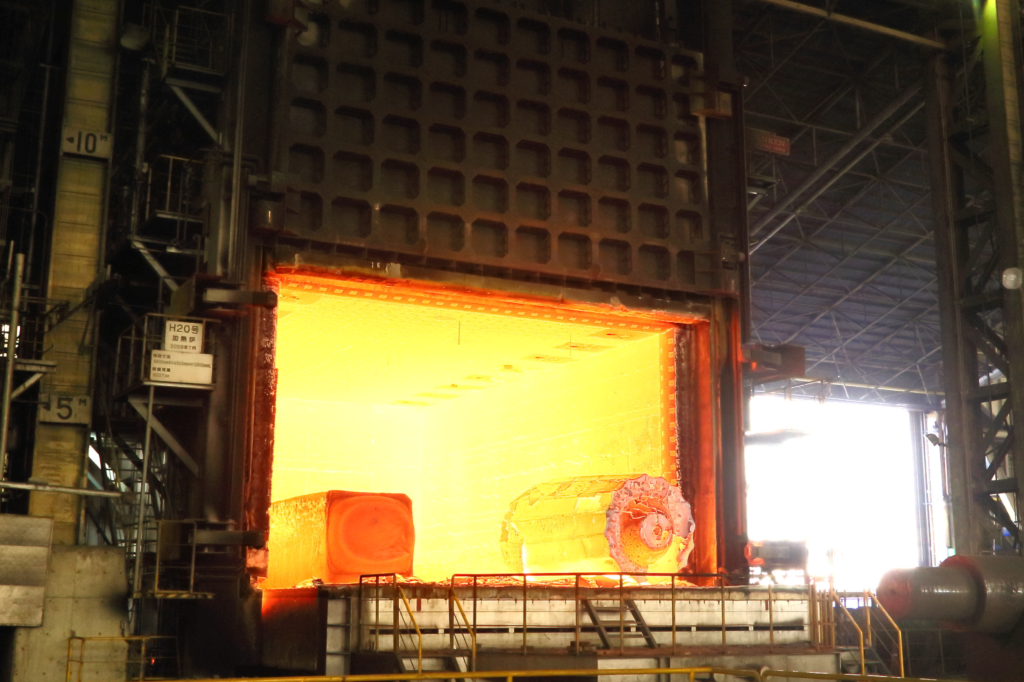

Fixed Furnace Bed Type Heating Furnace

Product Overview

This equipment is ideal for small-lot, high-mix production where processed materials are loaded and unloaded through a single frontage using charging and extracting equipment such as fork chargers and dedicated manipulators. These furnace have been delivered to a wide range of industries, and has been used at temperatures up to 1350°C.

Main Applications

- Heating furnaces for briquetting used in the production of crude steel

- Heating furnace for die forging and hammering

- Heating furnace for manufacturing rolled rolls

- Heating furnace for small and medium forging and ring mills used in the production of aircraft parts

- Heating furnace for large forging

Energy Saving Technologies

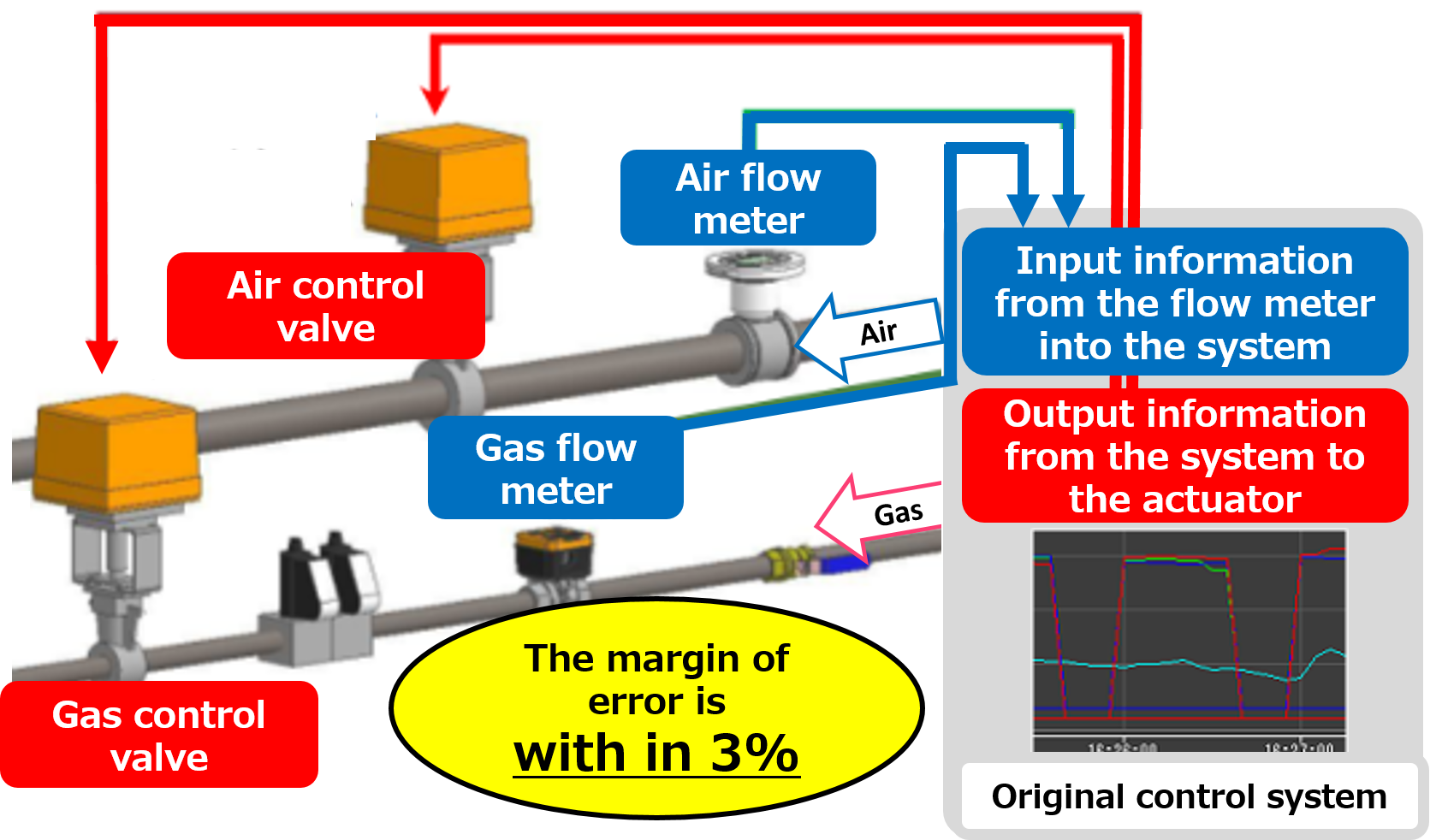

Energy-saving technologies include the use of energy-saving burners such as roof regenerative burners, multi-port regenerative burners, and slit regenerative burners; the introduction of mechanisms to minimize heat loss such as a waterless structures that does not use cooling water and a optimal mechanical seal mechanisms that seals the furnaces’ openings; and our unique individual flow control system that optimizes the air ratio for each burner in order to minimize energy loss.