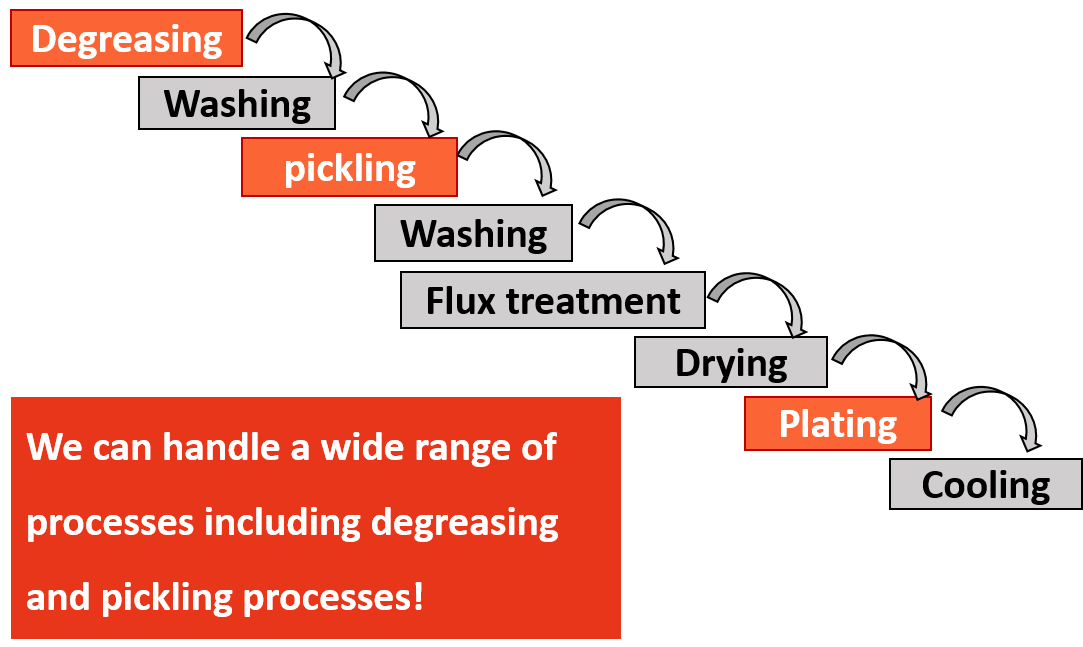

Possible to handle the entire line

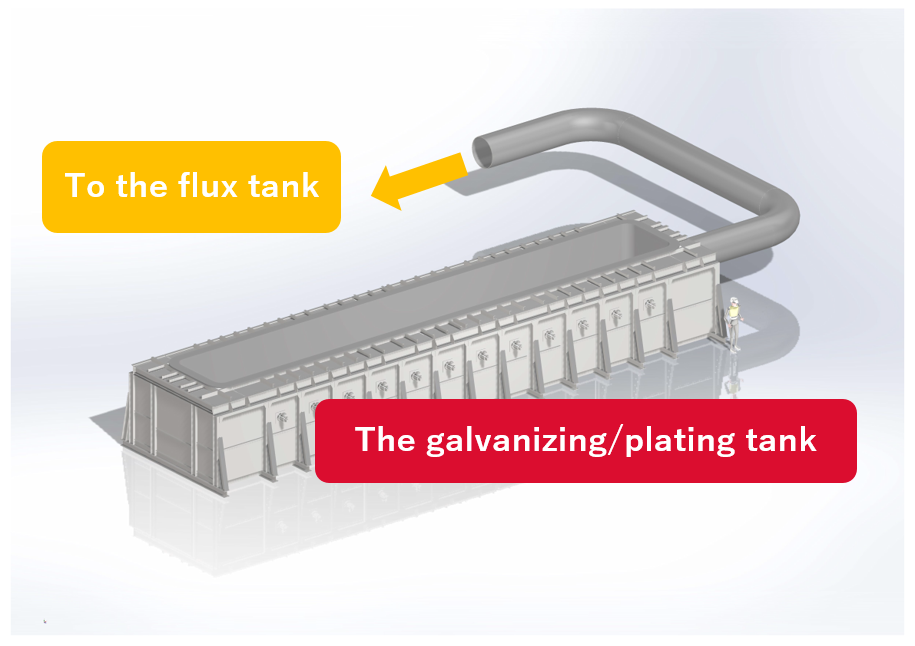

We can handle the entire line, including degreasing and pickling facilities necessary before galvanizing/plating.

2 types of plating furnace

Iron Pot Type Galvanizing Furnace

We have a total of approximately 200 installations ranging from small plating furnaces to large ones with effective lengths of up to 17 m.

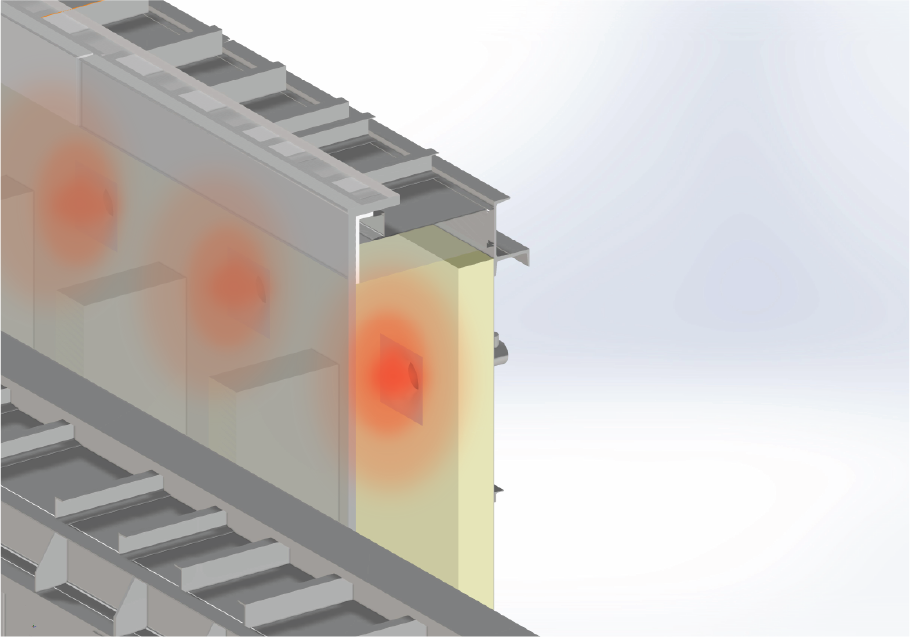

Two types of heating systems are available to prevent the life span reduction caused by local heating of the iron kettles.

Flame spreads radially along the wall of the burner surface.

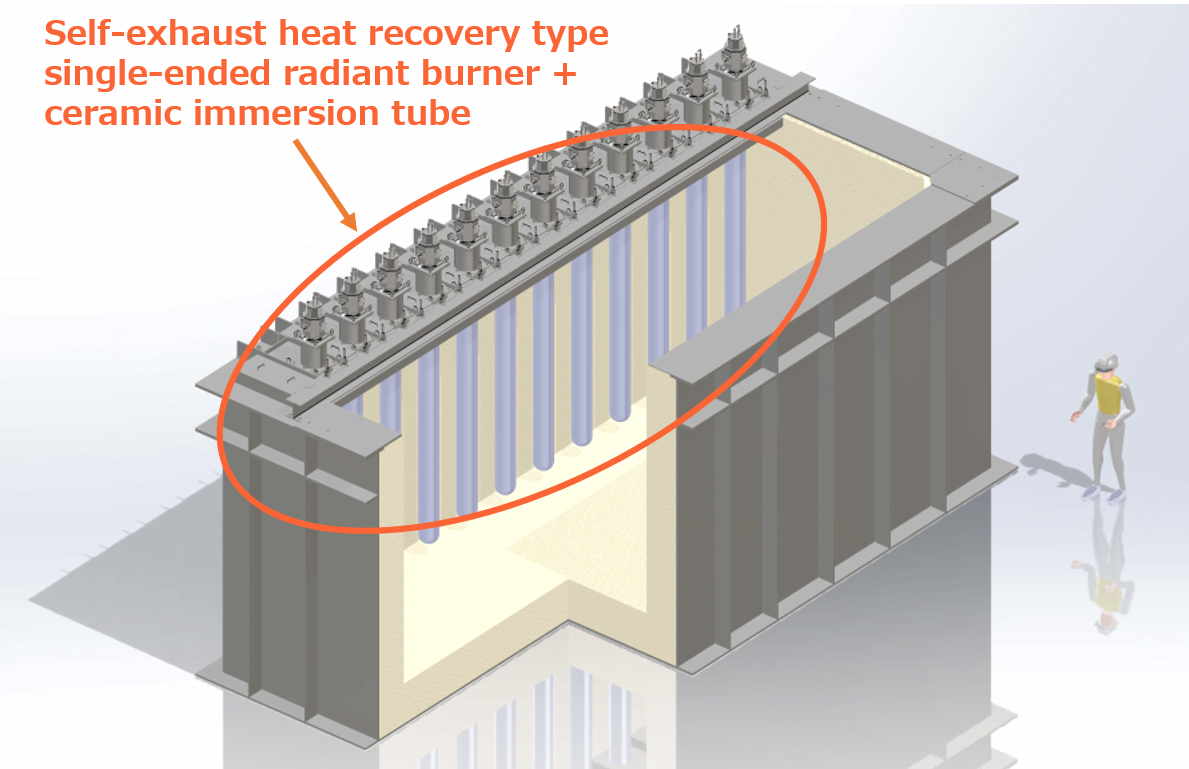

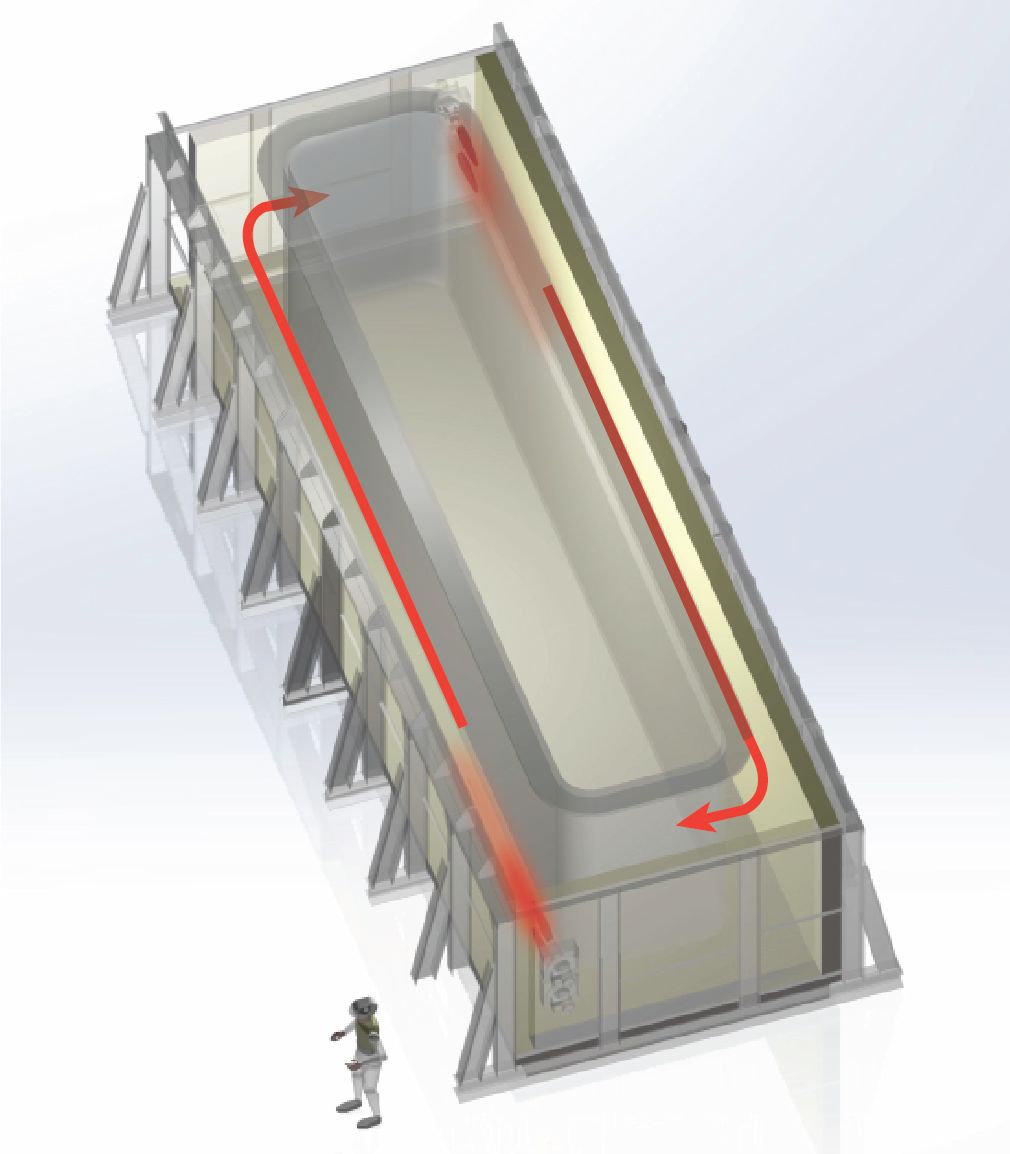

Ceramic bath type zinc plating furnace (CERARO)

This is a ceramic bath type plating furnace in which uses a special castable for zinc resistance installed in the equipment and the heat source ( self-exhaust heat recovery type single-ended radiant burner + ceramic immersion tube) is directly immersed in the molten zinc. Since no iron pot is used, there is Zero risk of molten metal leakage due to erosion, and the furnace can be used semi-permanently. In addition, it eliminates the need for production stoppages and production adjustments during kettle changeover periods, thereby improving productivity and running costs.