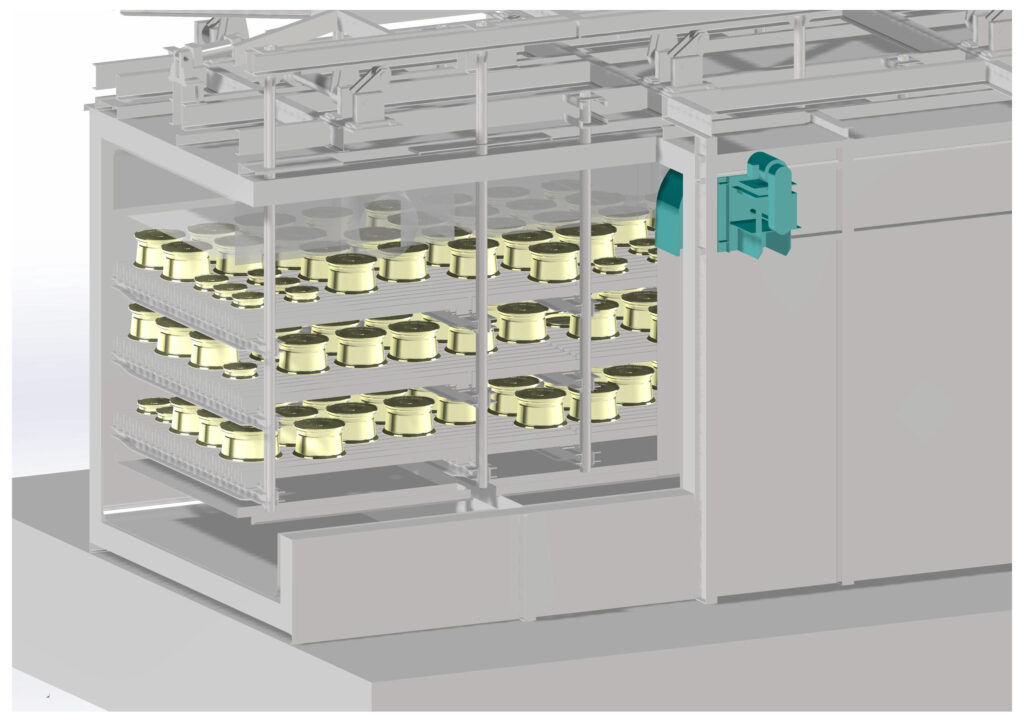

Rotary Type Heat Treatment Furnace

Product Overview

This equipment performs continuous heat treatment of aluminum products such as T4, T5, T6, and T7. Products are set on multi-stage treatment spaces (shelves/positions), and are conveyed and heated by rotating the treatment spaces. Fluid analysis is performed to optimize the structure in order to optimize the temperature and air velocity at each stage and each position ensuring that the optimal amount of energy is able to be transferred efficiently to each of the products’ positions.

Energy is saved by minimizing openings, eliminating jigs, etc.

Main Applications

- Heat treatment of aluminum wheels

- Heat treatment of cylinder heads and blocks

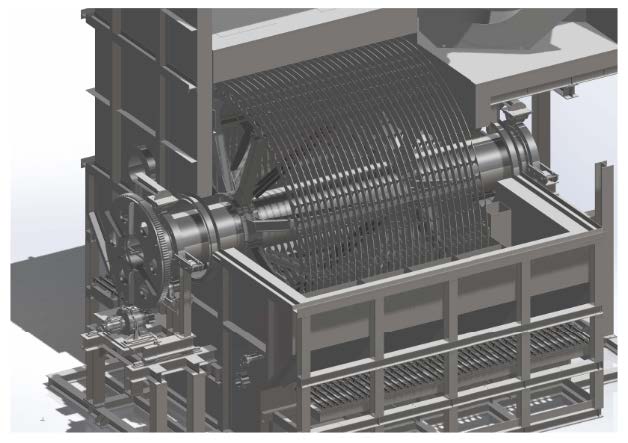

Roller Hearth Type Heat Treatment Furnace

Product Overview

This is a continuous heat treatment furnace capable of treating a wide range of products from T2 to T7. Products loaded in trays or baskets are fully automatically conveyed by electrically driven roller hearths, enabling the furnace to process a wide variety of products.

The optimal selection of hot air circulation fan and furnace interior design, taking into consideration the product shape, tray and basket weight, shape, and loading conditions, ensures improved heat transfer efficiency to the product and highly accurate temperature distribution.

Main applications

- Heat treatment of battery cases

- Heat treatment of cylinder blocks and a wide variety of products

Walking Beam Type Heat Treatment Furnace

Product Overview

This is a continuous heat treatment furnace using a walking beam conveying system, capable of treating a wide range of products from T2 to T7. The basketless system, which transports products without baskets or trays, saves energy and prevents uneven temperatures in each product, thus ensuring stable quality.

We have developed this intelligent walking beam system (patented) that can automatically transfer products of different sizes (e.g., aluminum wheels of different diameters) with a minimum pitch, enabling efficient transfer without wasting space. Furthermore, the compact furnace body combined with our unique hot air circulation system can be expected to save a great deal of energy (furnace surface area: approx. 25% reduction (compared to ours), electricity: 30% reduction (compared to ours)). In addition, by eliminating the conventional use of baskets, reduction in energy consumption and running costs are also possible.

Main applications

- Heat treatment of battery cases

- Heat treatment of cylinder blocks

- Heat treatment of wheels

Revolver heating furnace

Product Overview

This equipment is designed for the heat treatment of round billet products. A revolver structure is used for conveyance within the furnace. Once set in the revolver, the product moves through the furnace with only a rotating motion, providing excellent stability in the furnace.

The product insertion and extraction ports are designed with the diameter of the round billet + α, which makes the opening of the entire furnace very small, significantly reducing the opening heat loss during charging and discharging.

The conveyor system is designed without O-rings or bushings in order to reduce wear on parts.

An airtight shaft seal structure is used to reduce the risk of equipment burnout due to heat leakage from the furnace body seals.

Main Applications

- Pretreatment of aluminum billets for hot forging

Tray Type Heat Treatment Furnace

Product Overview

This equipment charges and extracts products using dedicated manipulators. By using multiple furnaces and common manipulators, it is possible to automatically process small-lot, multi-variety products.

Main Applications

- Heat treatment furnace for rocket tank domes

- Heat treatment furnace for aluminum products