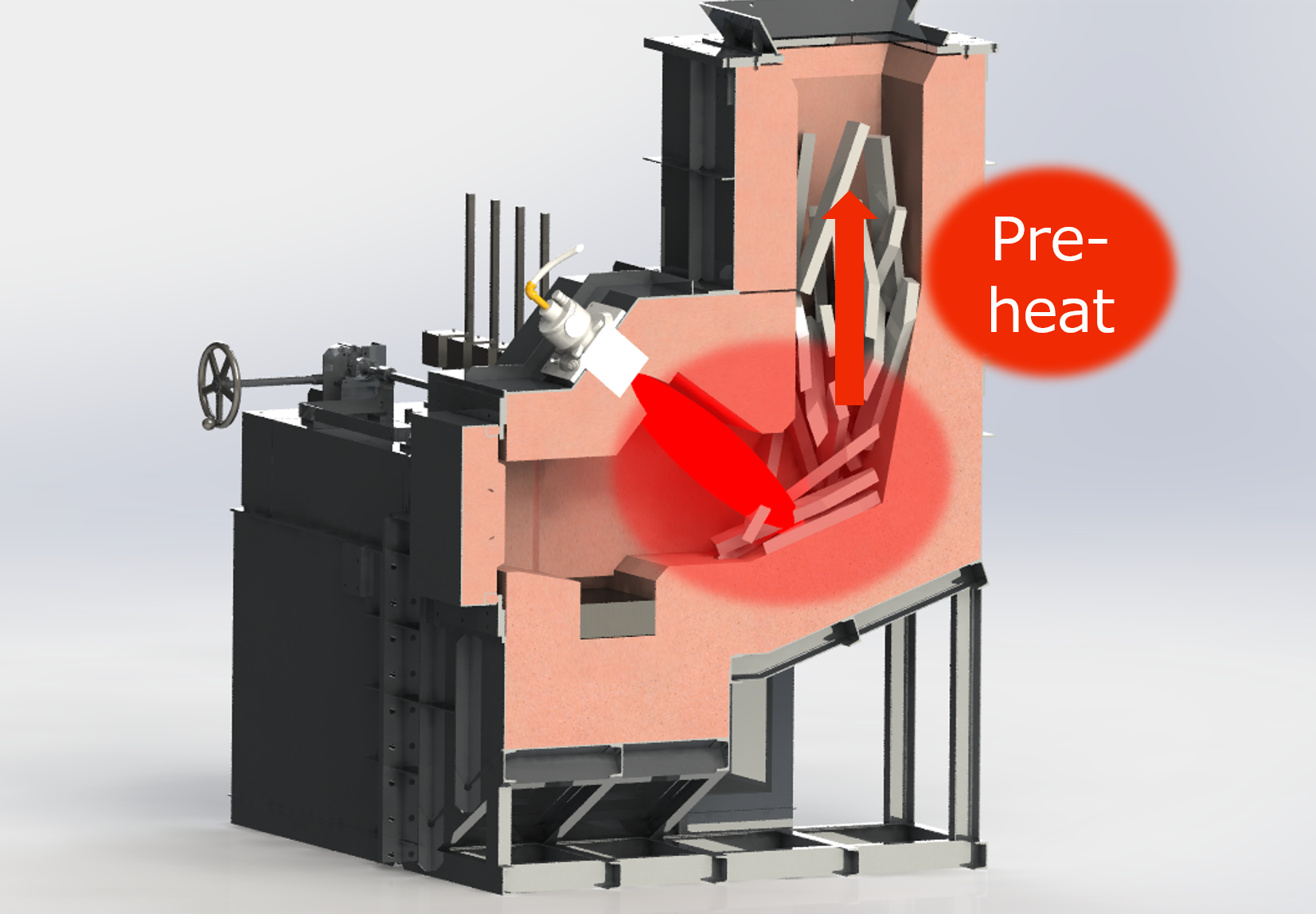

Rapid Melting Furnace (Sanken Meltower)

Product Overview

This is an aluminum melting furnace with more than 2,000 installations worldwide.

We have experience in melting capacities from anywhere from 100 kg to 7000 kg per hour.

Energy efficiency of approximately 60% is achieved by simply recovering exhaust gas heat from the tower, without using a complicated energy-saving system.

Aluminum melting furnaces are subject to high temperatures and strong impacts from the feeding of materials, so the equipment is subject to severe wear and tear. However; with our experience, engineering know-how and improvements to the furnaces in this field, as a result, many of our melting furnaces have been in use for more than 30 years.

Main applications

- Centralized melting furnace for aluminum casting (die casting HP, low pressure casting LP, gravity casting, etc.)

- Auxiliary melting furnace for AL serve

- Machine side melting furnaces for GIGACASTING

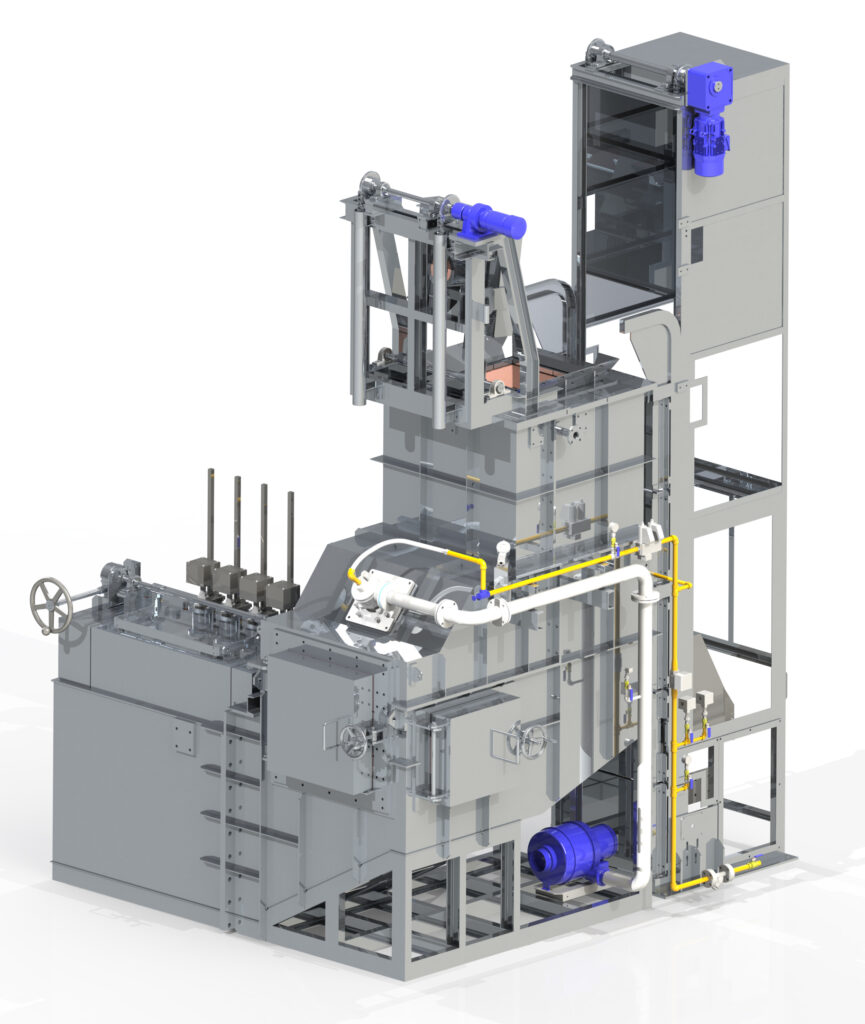

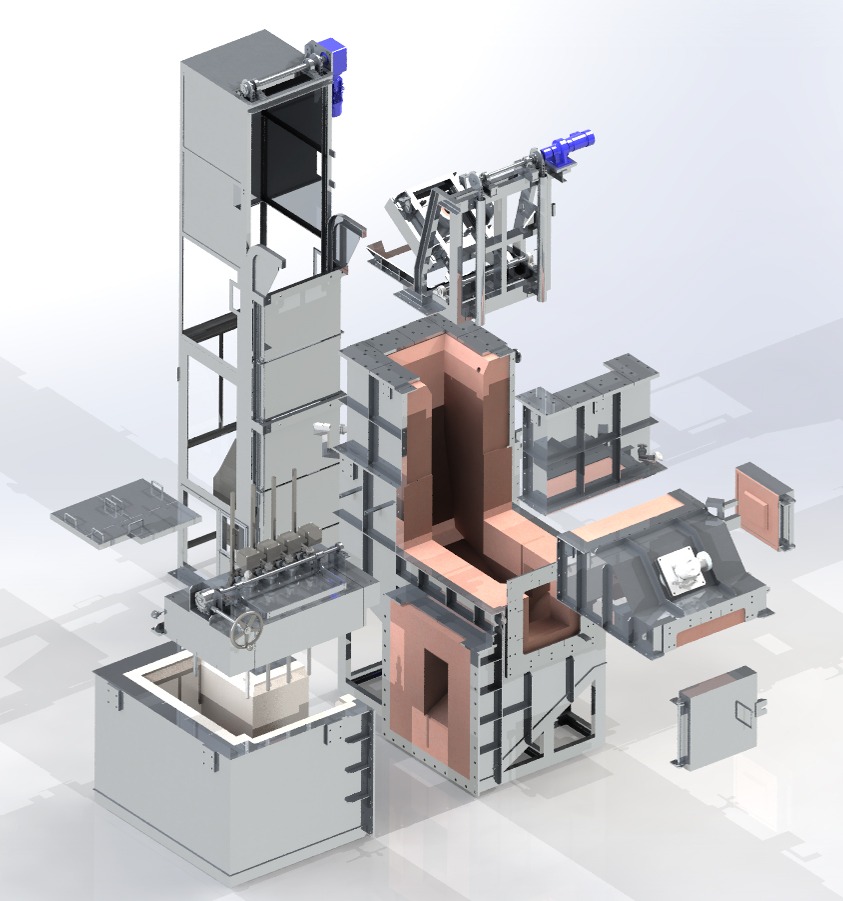

Hybrid type rapid melting furnace (Hybrid melter)

Product Overview

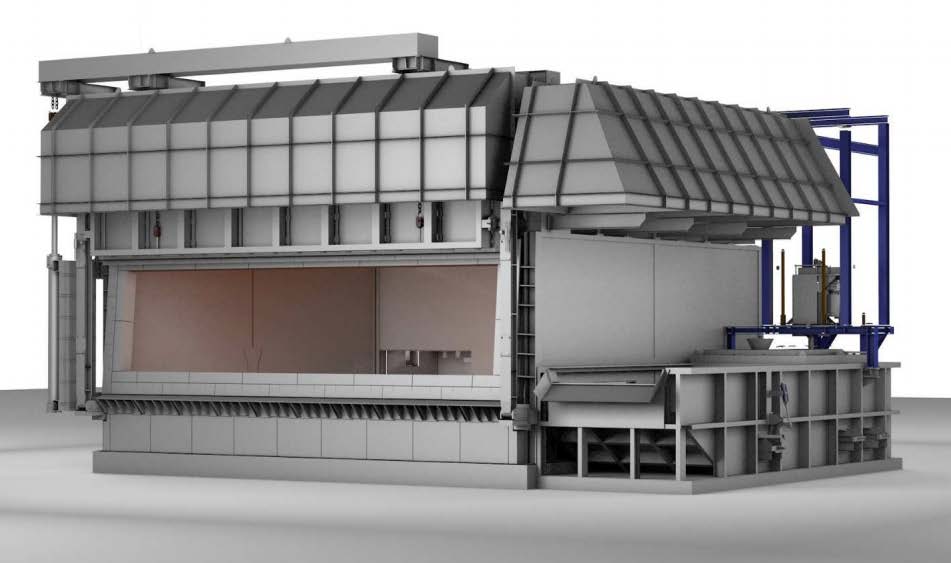

This is a tower-type aluminum melting and holding furnace featuring a hybrid (cross combination) of burner and heater technologies.

The compact furnace body reduces heat dissipation and the use of an original high-efficiency heater (SA heater) in the holding chamber reduces exhaust gas loss, resulting in energy savings of approximately 25% and a 10% reduction in CO2 emissions compared to conventional combustion furnaces.

The direct heat transfer heating of molten metal using a heater and the adoption of a precise control system enable the furnace atmosphere temperature in the holding chamber to be lower than the molten metal temperature, thereby preventing the generation of oxides.

Main Applications

- Dedicated melting and holding furnaces for small and medium-sized aluminum casting machines

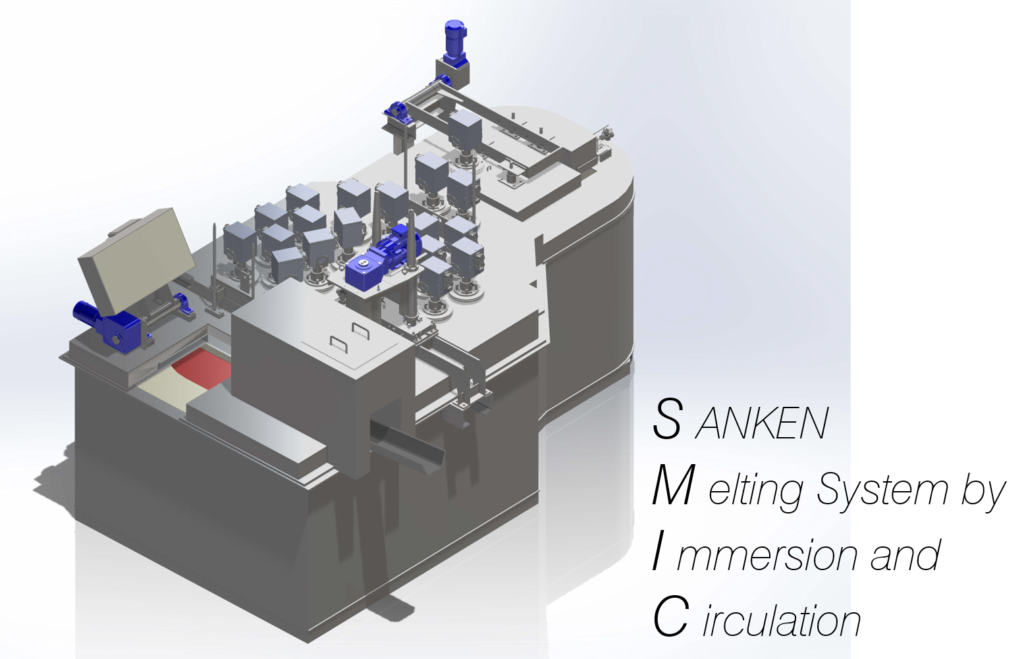

All-electric aluminum melting furnace (S-MIC)

Product Overview

S-MIC is an electric aluminum melting and holding furnace developed in collaboration with Tokyo Electric Power Co. By using an original high-efficiency heater (SA heater) instead of combustion equipment using fossil fuels as the heat source, this furnace is all-electric, energy-saving, and compact.

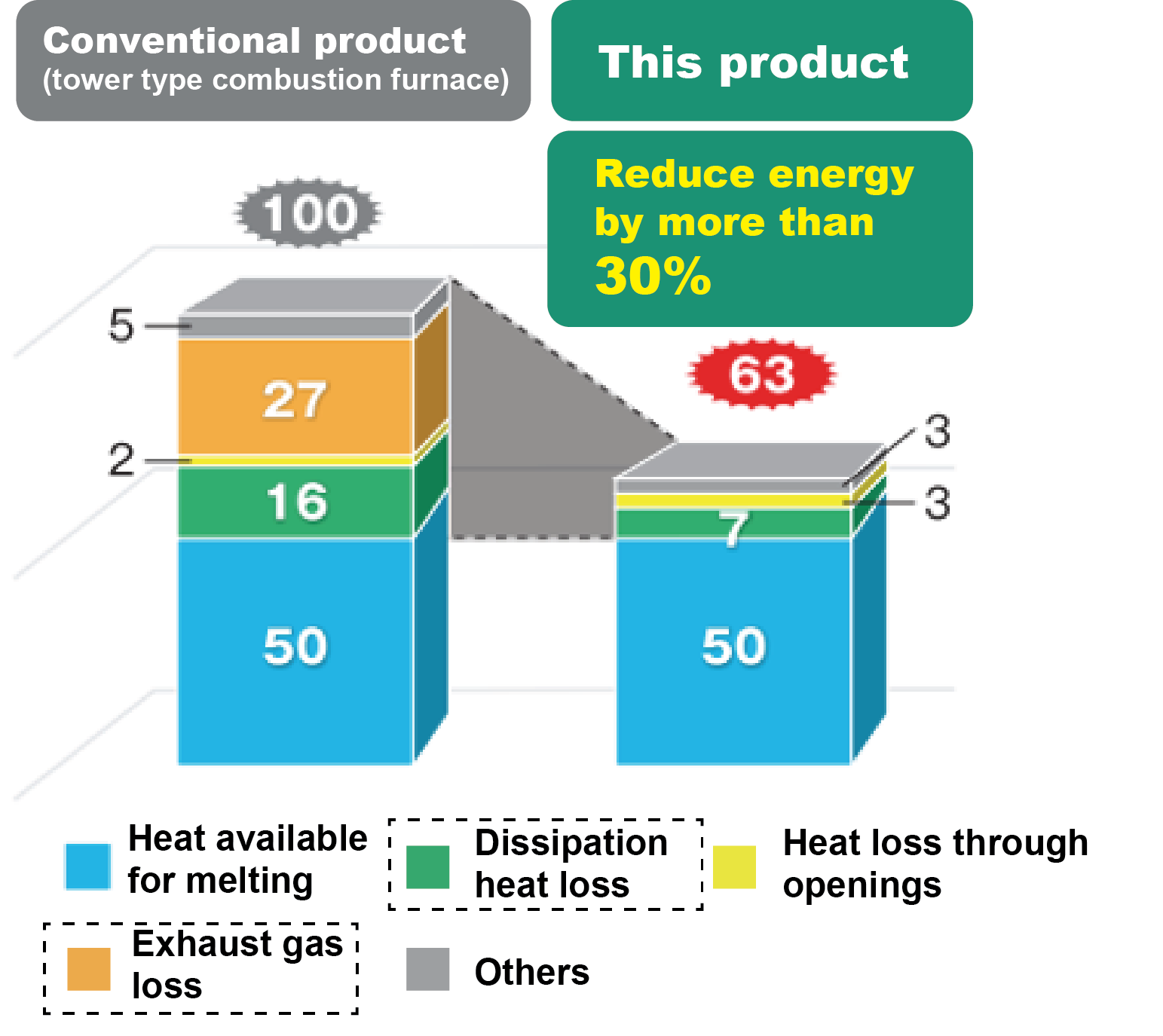

The furnace body heat dissipation and exhaust gas loss are greatly reduced, resulting in energy savings of 30% or more compared to our conventional furnaces. The all-electric melting line also achieves zero CO2 emissions from the plant.

Main Applications

- Dedicated melting and holding furnaces for small and medium-sized aluminum casting machines

- Medium size concentrated aluminum melting furnace

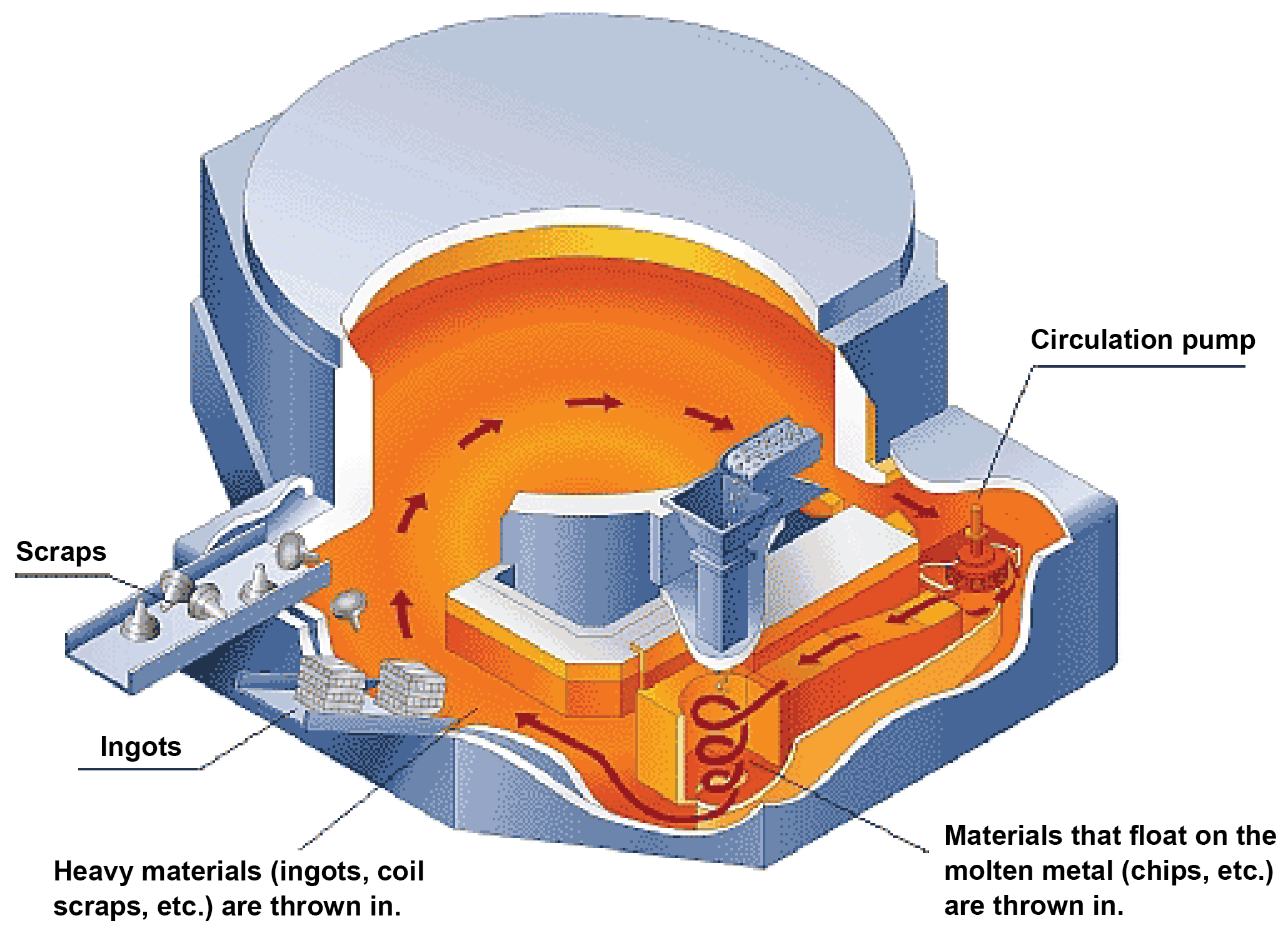

Sidewell type melting furnace and reverberatory furnace

Product Overview

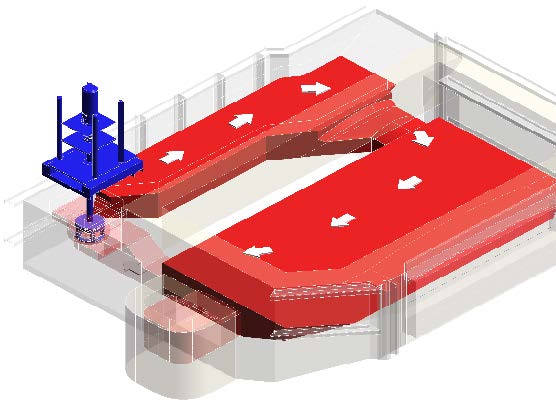

This is a highly versatile facility, which melts aluminum ingots, return materials, scrap materials, and other materials of any type or size. The side-well type melting furnace circulates molten metal in the side wells to perform immersion melting of materials. We have delivered equipment with a maximum capacity of 150 t/ch.

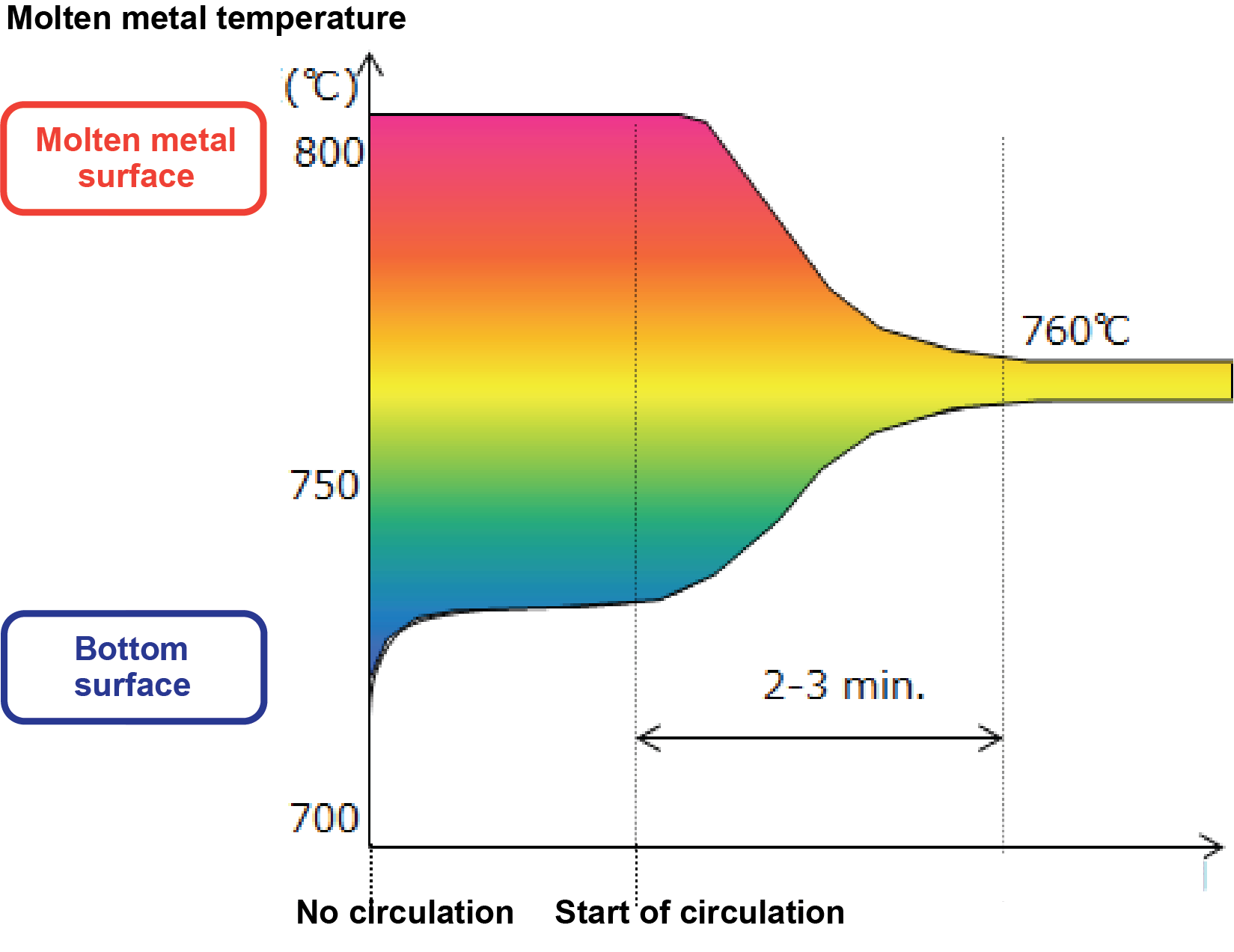

This equipment uses a regenerative burner that can recover exhaust gas heat. By circulating molten metal with a mechanical or electromagnetic circulation pump, the melting efficiency can be improved and the temperature distribution of molten metal can be made more uniform.

Main applications

- Melting of aluminum scrap materials

- Melting of aluminum chip materials