Features

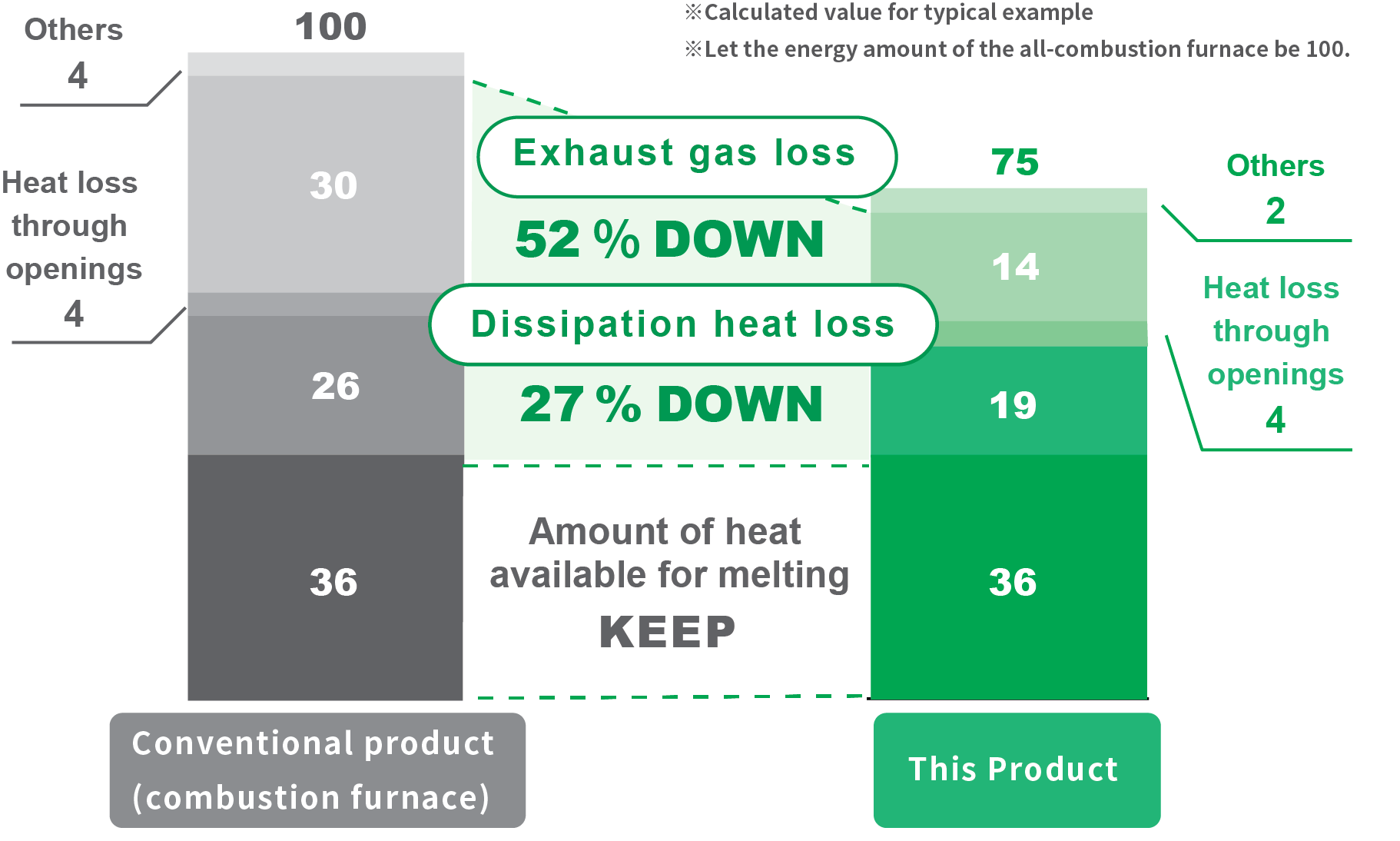

Energy saving

The compact furnace body reduces heat dissipation and the use of an original high-efficiency heater (SA heater) in the holding chamber reduces exhaust gas loss, resulting in energy savings of approximately 25% and a 10% reduction in CO2 emissions compared to conventional combustion furnaces.

High quality molten metal

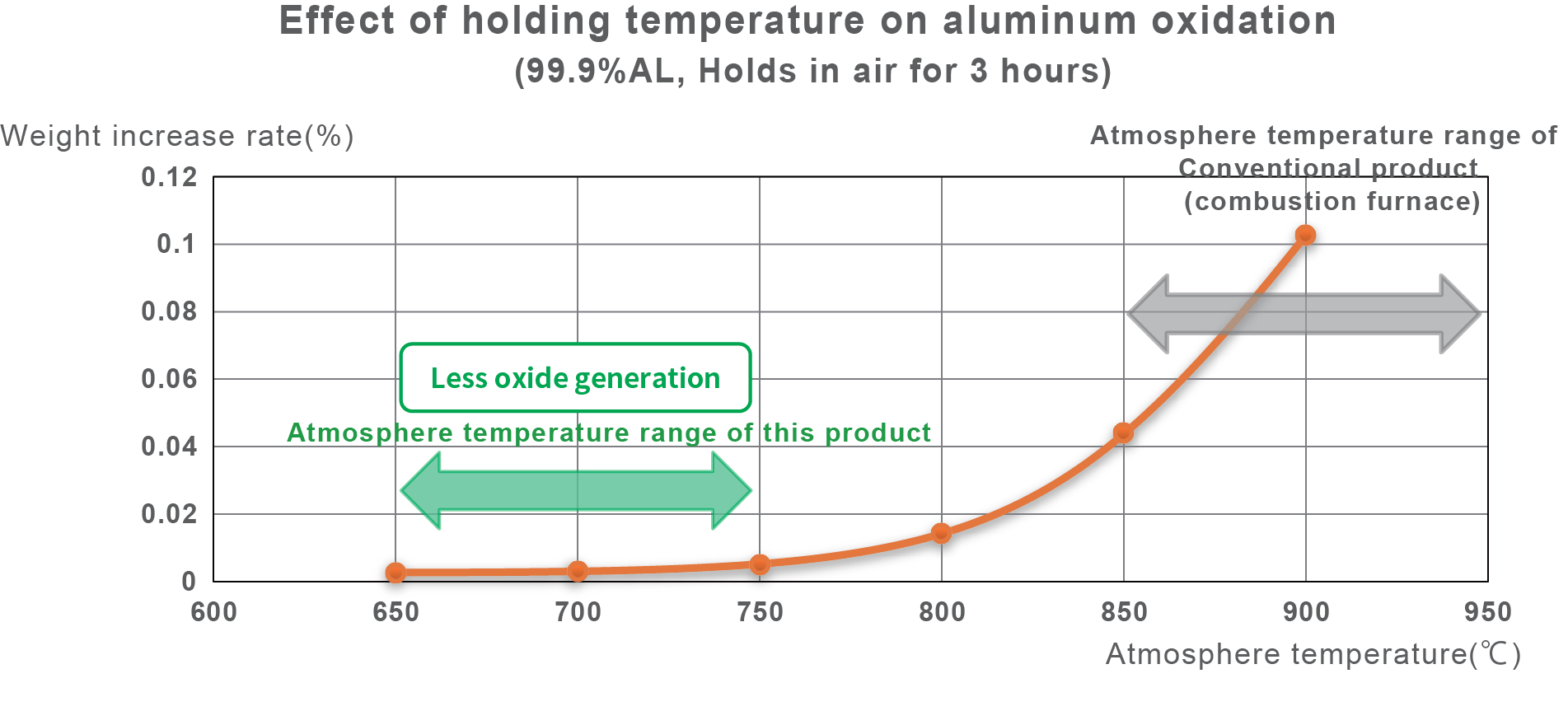

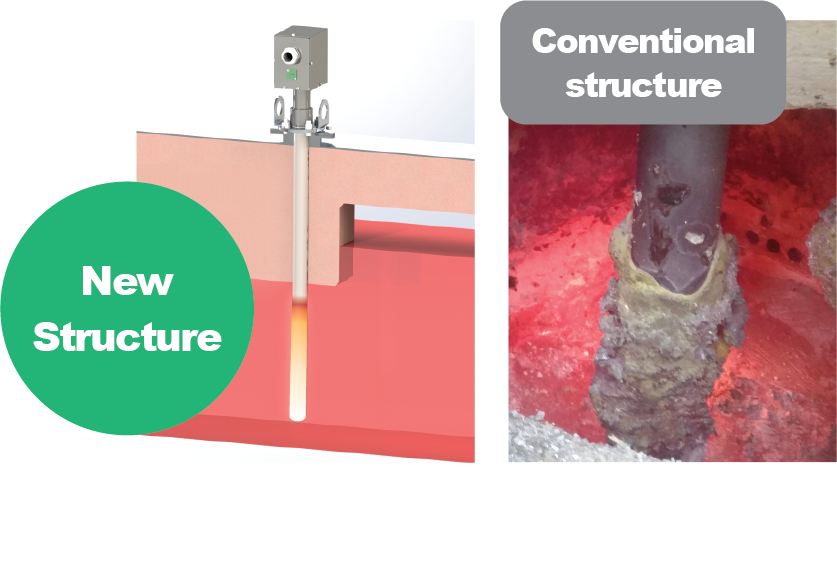

01 Direct Conduction Heating Prevents Oxide Generation

In an all-burning furnace, the atmosphere temperature in the holding room rises to 850 to 950°C, where oxides are likely to be generated. However, this equipment prevents the rise in ambient temperature in the holding room and the generation of oxides by directly heating molten metal by conduction heating with a heater.

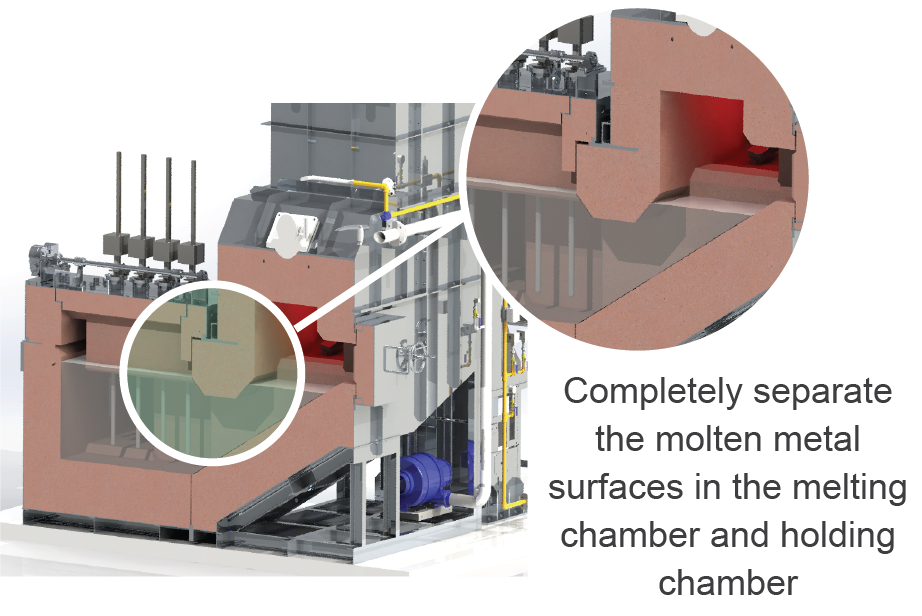

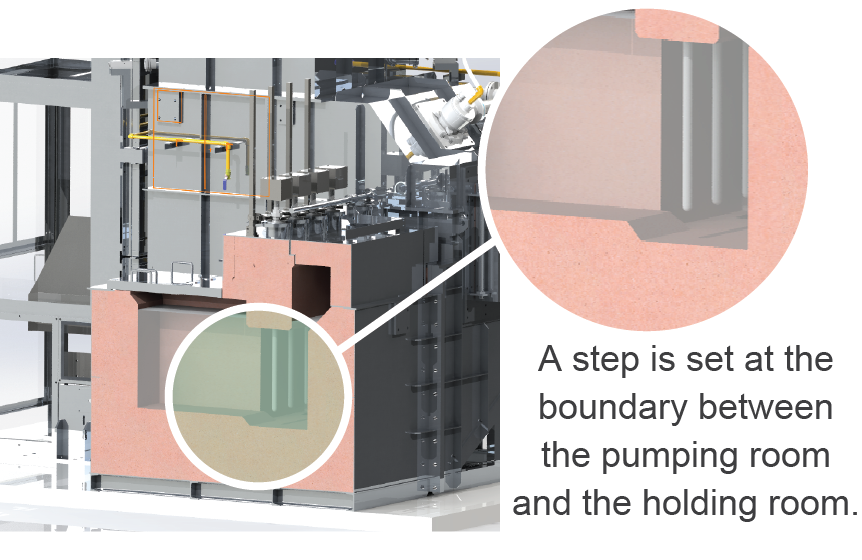

02 Structure to prevent oxides from being mixed in

The furnace structure is designed to prevent oxides generated in the melting chamber from being brought into the holding chamber.

Also, oxides do not adhere to the heater, eliminating the need for periodic cleaning.

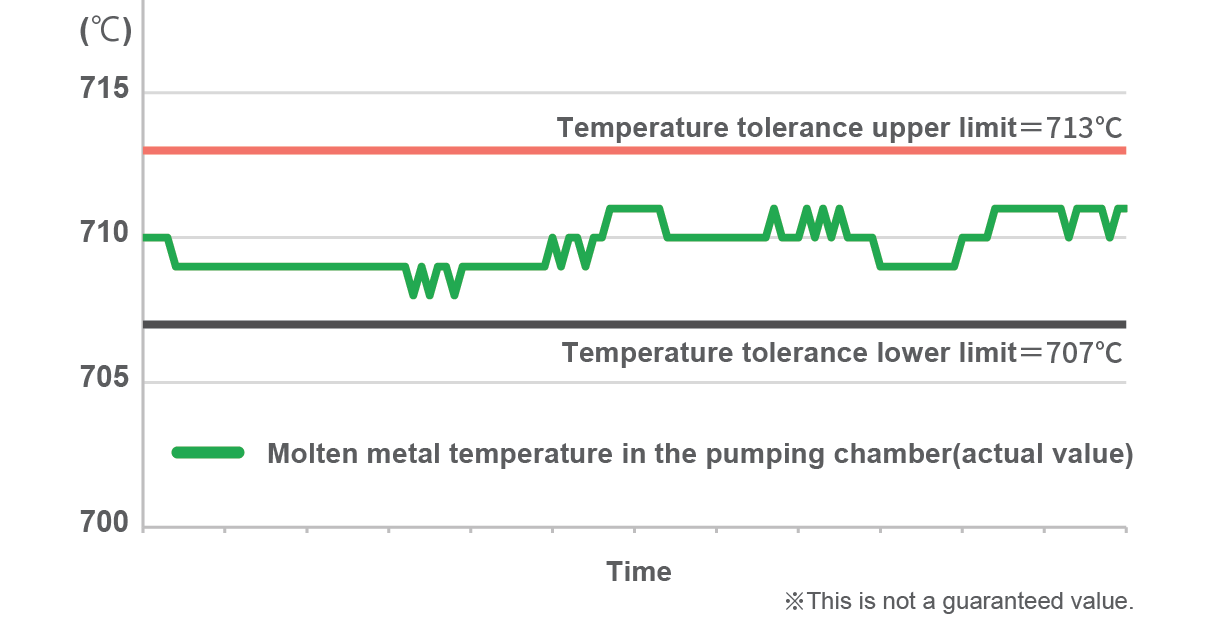

03 High controllability

The set temperature can be controlled within ±3°C.

04 Adoption of refractory material AL-II, which has less oxide adhesion and is easy to remove

The image below shows that the black oxides adhering to the entire interior wall before removal are cleanly gone after removal.

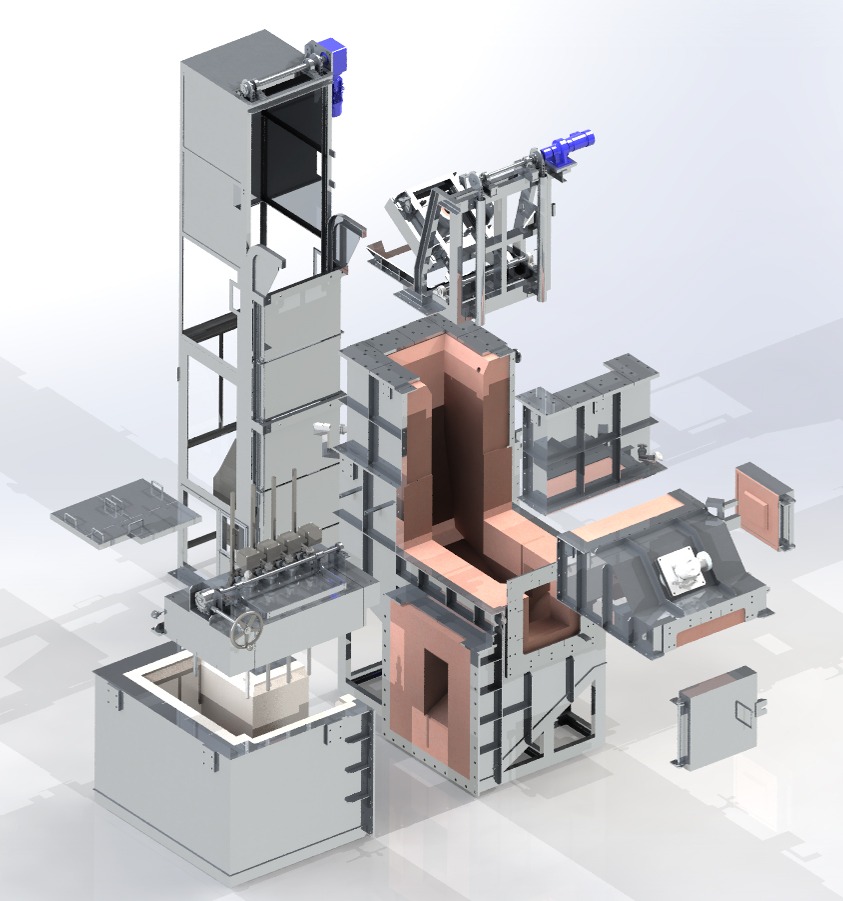

Short maintenance period

The structure allows parts to be exchanged modually, and the work can be completed in a short period of time, so maintenance work can be easily performed on weekends, without being restricted by the timing of long holidays such as GW and year-end and New Year holidays(*).

(*)The construction period varies depending on the layout and replacement parts, so please contact our representative for further details.

Variations

We have a lineup of various variations to meet the specifications required by our customers, such as melting capacity and effective output volume.

| Type | HBM- 100 | HBM- 150 | HBM- 200 | HBM- 250 | HBM- 300 | HBM- 350 | HBM- 400 | HBM- 500 | HBM- 600 |

|---|---|---|---|---|---|---|---|---|---|

| Melting Capacity(kg/h) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 |

| Effective output(kg) | 80 | 80 | 150 | 150 | 210 | 210 | 260 | 260 | 260 |

| Melting burner (kW) | 116 | 116 | 174 | 174 | 233 | 233 | 290 | 350 | 350 |

| Holding heater(kW) | 26 | 26 | 39 | 39 | 60 | 60 | 60 | 60 | 80 |

| Number of heaters | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 4 |

* The number of heaters is the minimum number required and does not include backups.