Products (Steel Areas)

Large Steel Ingot Reheating Furnace for Free Forging

Our car bottom batch reheating furnaces for free forging industry minimize heat losses by cooling waterless design and mechanical seal design sealing openings closely, and are energy-saving furnaces excellent in uniform heating performance using our patented roof-mounted multi-port regenerative burner technology. Also, they have realized both electric power-saving and low NOx emission, applying our own fuel-air ratio control technology per each individual burner. We have a lot of references of large reheating furnaces, including the world's largest one for 650 tons steel ingot.

Vertical Split Heat Treatment Furnace

Our unique split heat treatment furnaces have been developed rethinking furnace construction, seal mechanism, electric heater and temperature control system from a fundamental point of view so that both of the feature of vertical furnace and the benefit of split design can exist together. We have many references, ranging from small to large ones, in Japan and overseas countries. One of the benefits of sprit design is to move work-piece horizontally, which requires no conventional deep pit and high-lift overhead crane, thus safety operation also can be enhanced.

Furnace Body Traveling Heat Treatment Furnace

Car bottom design has been traditionally used for large batch heat treatment furnaces. We have developed furnace body traveling heat treatment furnace by changing our way of thinking: not car bottom but furnace body to travel. This design can reduce costs of foundation and car bottom repair, and can produce a lot of benefits such as improved workability and safety during loading/unloading work-pieces, enhanced product yield by reducing deformation of work-pieces during heat treating, etc. Also, our batch heat treatment furnaces are equipped with not only self-recuperative burners, but also regenerative burners which have been said to be difficult to apply in medium or low temperature heart treatment furnaces however recently have been put into practical use by our newly developed combustion control technology, achieving substantial energy-saving effects.

Coiling Furnace

Coiling furnace is thermal equipment used to coil hot stainless steel sheet at high velocities, heat and hot it during rolling in Steckel mill. s, heat and hot. This is one of our unique products. Our coiling furnaces include waste heat recovery system by recuperator and low NOx emission burners as standard.

Non-oxidation Reheating Furnace for Rolling Special Steel

These non-oxidation continuous furnaces are used to reheat special alloy steel such as nickel alloy prior to rolling and application of our newly developed special hearth roller allows us to heat up to atmosphere temperature of 1,300℃ for the material dimensioned up to 1,350 mm wide, 200 mm thick and 12,000 mm long.

Continuous Reheating Furnace

Recently, application of regenerative burner has mass appeal, in addition to this, we incorporate state of the art control systems including our own fuel-air ratio control technology per each individual burner, and have high reputation from our customers for energy saving as well as improved productivity.

Heating Furnace for Hot Pressing

In order to design a specific heating furnace meeting with customer's own product characteristic, we examine the best suitable heating conditions on temperature and time required with our test furnace, according to customer's various requirements such as shapes and thickness of material, with or without galvanized, thickness of galvanized layer, etc.

For the furnace style, we principally apply a roller hearth design, but we can offer in walking beam or heat-proof conveyor designs. For the heat source, electric heating design or gas-fired design lowering oxygen level in the furnace under the low fuel-air ratio combustion is available.

Ceramic Bath – Zinc Galvanizing Furnace

We are proud of the top market share of zinc galvanizing furnaces in continuous ones for hard steel wire such as wire rope and soft steel wire such as fence as well as batch ones for large steel structure such as bridge. For the continuous galvanizing line, we have newly developed fully-electrified zinc galvanizing facility as well as highly-efficient and fume-shield acid pickling tank. A substantial energy-saving version, using a combination of self-recuperative burner (Germany-made REKUMAT burner series) and immersion ceramic tube which heats molten zinc from within, is also available.

We make a proposal of a ceramic bath design which can cope with Zn-Al galvanizing. Ceramic baths do not require periodic replacement unlike conventional steel kettles, which can reduce maintenance costs and zinc metal losses generating from replacement of the kettles, as well as, dramatically reduce the risks of sudden production shutdown and opportunity losses caused by metal run-out accident.

Continuous Steel Pipe Heat Treatment Furnace

Our roller hearth steel pipe heat treatment furnaces are equipped with our newly developed side burners with radiation tube, and our suitable arrangement of the said burner system improves temperature uniformity of the cross direction of the furnace and facilitate set up longitudinal heating patterns within the furnace. Also, we design freely each length for heating, soaking and cooling zones, according to the customer's needs of heat treatment for elongated pipes. Also, we protect pipes from scratching in the furnace by our own pipe guide mechanism.

In order to be energy-saving design, EBC (easy burner control) system that can combust gas with preheated combustion air through a recuperator at proper air-fuel ratio at any turn-down ratio is applied.

Roll Rapid Differential Heating Furnace and Heat Treatment Furnace

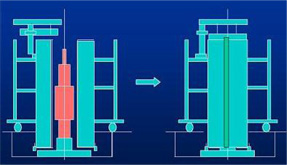

These are dedicated furnaces for heat treatment of mill rolls which are used for hot rolling process. Rotating equipment of roller and heating length of in-furnace can be remotely set up, according to diameter and length of the roll to be treated.

Furnace body is designed to be split to accept a roll and a lot of radiant cup burners installed in the furnace walls can heat body surface of the roll rapidly and uniformly.